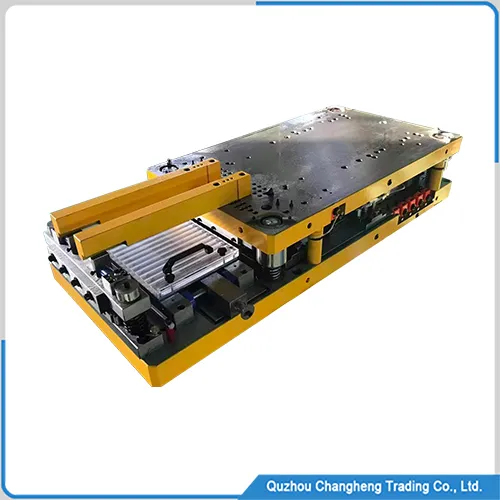

machine outline

This equipment uses a 2.5kw motor as the primary power source, and its structural design is effortless, making future maintenance and repair work very easy. Workers do not need to undergo strict training and can proficiently master all the operations of the fin winding machine in a short time.

This machine is already equipped with a central axis positioning device for the tube, which can effectively control the operation of the coaxial core during the high-speed production of finned tubes without worrying about the centrifugal force generated during production, causing tube bending.

This machine can produce fin tubes with a maximum length of 6 meters, requiring only a simple tool replacement. It can produce tubes of different diameter sizes, and the height and spacing of fins can also be easily changed. One machine can meet 90% of the fin tube types on the market.

Fin winding machine Technical Data

| ITEM | DATA |

| Fin material | aluminum |

| Pipe material | iron copper stainless steel titanium alloy |

| Fin thickness | 0.1-0.4mm |

| Machine weight | 560kg |

| Fin type | L type |

| Pipe diameter | φ13-38mm |

| Production speed | about 250m/ 8h |

| External dimensions | 155*65*125cm |

Fin winding machine features

- Simple structure:

Workers do not need training and can easily take up positions

- Flexible design:

With the need to replace simple tools, different sizes of fin tubes can be produced

- Winding process:

There is no need to weld fins and tubes, and the winding process is used to tightly connect the fins and tubes, which is firm and has a good heat transfer effect

- The spacing between the fins is uniform:

The fins of the fin winding machine are L-type, which are evenly distributed on the pipes without wrinkles and are very beautiful

wechat

wechat