Temperature Profiling working video

Summarize

Temperature Profiling is an advanced instrument designed specifically for industrial high-temperature applications, which can accurately measure and record the temperature distribution inside the furnace.

This device typically includes multiple channels, each of which can independently collect temperature data.

The temperature profiler can wirelessly transmit the collected temperature data to connected computers or mobile devices through the built-in WIFI communication module.

Operators can remotely monitor the temperature changes inside the furnace in real-time, and perform data analysis and processing as needed. To help engineers optimize process parameters, and improve product quality and production efficiency.

In addition, temperature profilers usually have data storage capabilities, which can record long-term temperature data for post-analysis purposes.

More related devices

Why choose our Temperature Profiling

1, Multi-channel monitoring

The temperature profiler is equipped with 10 independent temperature acquisition channels, which can simultaneously monitor the temperature at different positions of the product

2, High-precision measurement

The use of susceptible temperature sensors ensures the accuracy of measurement data and meets the strict requirements of industrial applications for temperature control.

3, Wireless Connection Technology

Built-in WIFI module facilitates connection with computers or other intelligent devices, enabling remote monitoring and data transmission, and improving work efficiency.

4, Data recording and analysis

Equipped with a data storage function, it can record and store temperature data, facilitate historical data analysis, and assist in process optimization and decision-making.

5, Professional technical support

We provide professional technical support and services to ensure that customers receive timely assistance and consultation during use.

6, Customized services

Based on the specific needs of our customers, we can provide customized services, including configuration of special channel numbers, selection of sensor types, etc.

Technical parameters of temperature profiler

Operational principle of Temperature Profiling

The working principle of temperature profilers is based on multi-point temperature measurement technology. These sensors are usually thermocouples, which can convert the measured temperature into electrical signals.

In practical applications, temperature profilers are installed in insulated boxes and enter the interior of industrial furnaces. Each sensor detects the instantaneous temperature at its own location and converts this temperature value into an electrical signal.

Then, these electrical signals will be transmitted to the data acquisition unit of the Temperature Profiling instrument.

The data acquisition unit is responsible for receiving signals from all sensors and converting them into digital data.

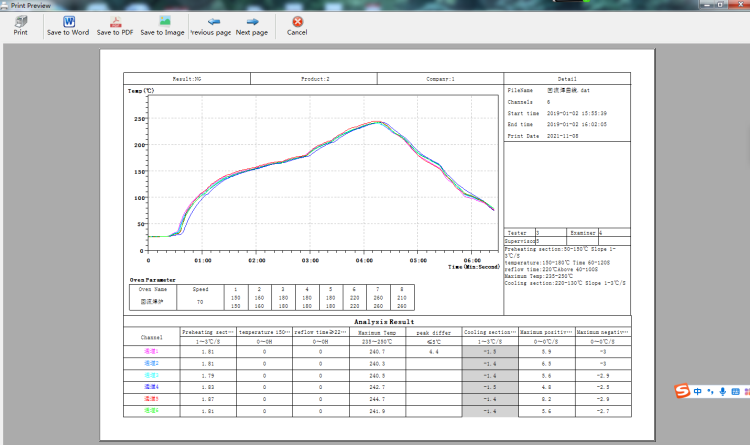

Afterward, the computer software generates temperature profiles, performs complex data analysis, and provides real-time feedback.

Through wireless communication technology, such as WIFI, temperature profilers can transmit the collected data in real-time to remote computers or mobile devices.

Users can view and analyze temperature profiles through dedicated software, monitor the temperature distribution inside the furnace, and make adjustments as needed.

Temperature Profiling application

With the advancement of industrial technology, the application of temperature profiling instruments in many high-temperature control fields has become increasingly widespread, mainly reflected in the following aspects:

1, Spraying and baking paint:

During the spraying and baking paint process, in order to ensure the adhesion and drying quality of the coating, it is necessary to precisely control the temperature inside the oven.

The temperature profiler can monitor and record the temperature distribution of various parts inside the oven, ensuring uniform and consistent temperature during the paint baking process.

2, Metal annealing:

The metal annealing process requires heating and insulation of metal materials at specific temperatures to improve their microstructure and physical properties.

The precise temperature data provided by the temperature profiler can ensure that the material meets the expected performance indicators.

3, Aluminum brazing:

In industries such as automotive, aerospace, and shipbuilding, aluminum is widely used due to its lightweight and high-strength characteristics.

During the aluminum brazing process, the temperature profiler can monitor the real-time temperature of the welding area and its surroundings, helping engineers optimize welding parameters and ensure the quality and strength of the welded joints.

4, Food and medical:

In the fields of food processing and medical device manufacturing, temperature control is crucial for ensuring product quality and safety.

The temperature profiler can monitor the temperature distribution during food baking, sterilization, and other processes, ensuring that the temperature meets the specified standards, thereby ensuring the quality of products and the health and safety of consumers.

wechat

wechat