Machine Outline

This extruded finning Machine is mainly suitable for manufacturing key fin tube parts such as industrial heat exchangers, coolers, and heat dissipation equipment.

Compared with ordinary equipment, the finned tubes produced by the extrusion fin machine have higher strength because this equipment adopts rolling technology, and the aluminum material is forcibly forming and attached to the outside of the metal tube through a mold.

During this process, the metal is extruded into the desired fin shape while keeping the inner tube’s size and shape unchanged. This process can effectively improve production efficiency and ensure the strength of fin tube usage.

Extruded Finning Machine Features

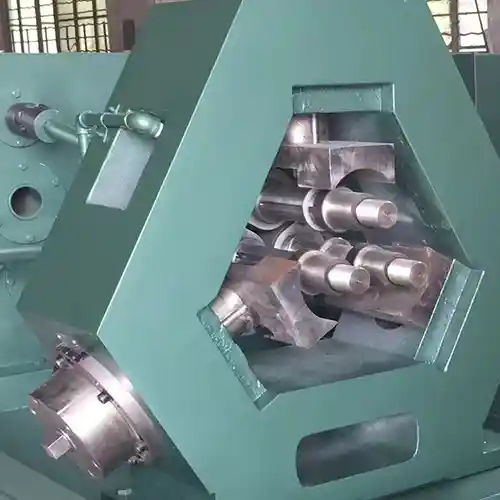

3 sets of roller extrusion molding

This machine adopts three sets of roller extrusion molding technology, with the three sets of rollers arranged in an isosceles triangle layout to ensure the smooth output power of the equipment.

During production, three rollers roll at the same speed to compress the metal outer tube to the outside of the inner tube, forming the desired fin shape. Package the entire inner tube.

During this production process, the extrusion machine requires precise control of the force and speed of the rollers to ensure the accuracy of the size of the finned tubes.

Automatic coolant system

The extruded finning Machine has an automatic cooling system that effectively cools three rollers during production. Reduce the rollers’ wear and improve the machine’s service life.

All cooling liquid recycling achieves automatic cooling during recycling. Ensure long-term high-speed production of the machine.

Simple structure

The structure of the extrusion fin machine is simple, mainly composed of the main engine, roller mold, coolant, control system, Gearbox, etc. The gear is made using a one-time forming powder metallurgy technique.

This extruded finning Machine does not require complex control systems, reducing production costs and maintenance difficulty. In addition, operating this machine is simple and doesn’t require many professional skills.

| ITEM | DATA |

| Fin pipe length | 0-15m |

| Fin height | 7-16mm |

| Fin thickness | 0.22-0.45mm |

| Outside fin materials | Aluminum Copper |

| Inside tube materials | SS304 Copper Iron |

| Tube Outer diameter | 25-77mm |

Extruded finning Machine advanced function

The machine adopts a replaceable roller mold design, allowing users to replace the roller mold cheaply and produce bimetallic fin tubes of different sizes. This friendly design can save users a lot of money and meet the needs of different customers.

The machine has three sets of roller molds arranged, and the power of each set of rollers is connected to the gear through a universal joint. Users can easily adjust the channel size of the rollers to produce fin tubes of different diameters.

This means that without changing the fin pitch size, A roller mold can produce fin tubes of various diameters.

Extruded finning Machine working video

Extruded finning Machine summary

In summary, the equipment provided by Changheng is a high-precision fin tube production device that can produce fin tubes of various sizes at a higher cost, ensuring the quality and production efficiency of finned tubes.

This device can be used in many fields, such as electricity, the chemical industry, and petroleum etc. If you are looking for such a machine, join Changheng. We will fully demonstrate our advantages and provide strong technical support for your industrial manufacturing.

wechat

wechat