Machine Overview

The spiral tube machine is mainly driven by an 11kva motor, which provides strong power to rotate three sets of roller molds and extrude metal tubes into a spiral shape.

This tube type is widely useing in heat transfer solutions, such as power generation, petroleum and weather, chemical industry, etc.

The equipment has an independent coolant circulation device to ensure that the roller mold always maintains the best state during use, extending the service life of the mold,

The replaceable design of the spiral roller mold on this machine allows users to customize the mold according to the size of the spiral tube, meeting their requirements for heat transfer efficiency. This low-cost mold change design reduces the factory’s operating costs and meets customers’ diversified needs.

Spiral tube machine data

| ITEM | DATA |

| Tube material | copper, stainless steel, iron |

| Tube diameter | 12-25.4mm |

| Power supply | 380V/50Hz |

| Voltage | 11 kva |

| Machine Color | Green |

| Cooling type | automatic circulation |

| roller Mold | replaceable |

| tube Type | Spiral |

Spiral tube machine advantage

- Quickly replace molds

The roller mold is an independent block made of CNC machine tools and hardened by vacuum quenching. It can quickly change to achieve production of various sizes, meeting all customer requirements.

- Simple control device

The spiral tube machine only has three simple control buttons, and workers can quickly master the regular operation of the equipment without the need for complex training work.

- Equipped with a circulating cooling device

This machine has a device for circulating coolant, which integrates cooling and recovery through scientific design,

does not occupy the space of the machine and ensures that the heat by the mold extrusion is quickly cool

- Reasonable structural design

The device has undergone major design updates, and its structure is reasonable and operates smoothly. Maintenance costs that not need during normal production processes

- Produce spiral tubes of any length

The two sides of this device are hollow out; theoretically, it can produce pipes of any length. We recommend that the maximum length not exceed 6 meters for easy transportation.

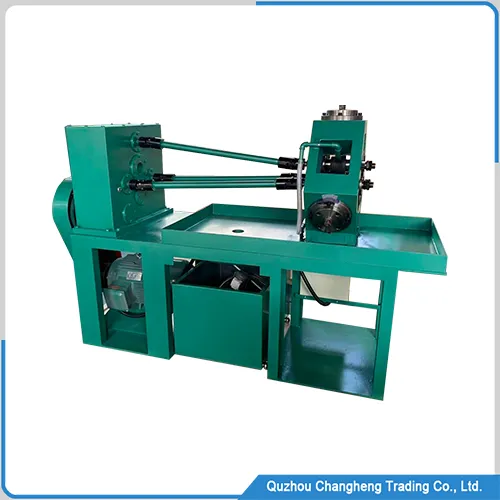

Spiral tube machine appearance

The bottom layer of the device’s exterior is rust-resistant paint, and uneven areas on the surface are filled with high levels of glue.

The machine’s appearance is a paint-drying process, and the default color is green. We can customize the color according to user requirements,

Please let us know if you have a favorite color and if the machine is placed in the workshop to create an overall aesthetic. You do not need to pay any cost; we can meet your requirements.

Spiral tube machine working video

Requirements for coolant

During the automatic production process of this spiral tube machine, the mold squeezes the metal tube, generating a large amount of heat. Ordinary machine tool saponification solutions cannot meet the cooling requirements of this equipment,

To ensure the mold’s service life and the machine’s stable quality output, it has higher requirements for the coolant, so users must purchase the original slurry saponification solution, which will have a better effect after dilution according to the proportion.

Usually, we provide a 500ml coolant sample, and it is not wrong for users to purchase it based on this sample.

wechat

wechat