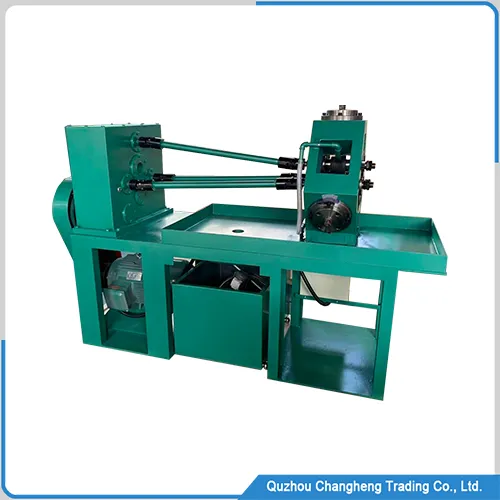

Machine Outline

This tube finning machine is suitable for producing two different metal finned tubes. It produces pipes with different pitches by replacing the blades of the extrusion roller.

We have upgraded the extrusion roller structure compared to the previous generation of machines to make blade replacement easier and improve blade accuracy.

We have added a scale to the machine’s adjustment position to produce different pipe diameters. Now, we can visually adjust the size to improve work efficiency further.

The tube finning machine has three rollers that simultaneously extrude aluminum material, and all the rollers have power.

A plum blossom universal joint between the roller connecting rod and shaft makes the connecting rod safer with almost no power loss.

Tube finning machine data

| ITEM | VALUE |

| Outer Fin thickness | 0.2-0.4mm |

| Outer Fin material | Aluminum & copper |

| Base pipe size | 10-38mm, 8-51mm |

| Base pipe material | SS304 SS201 Aluminum Copper Alloy |

| Delivery time | 60-65 days |

| Outer Fin height | <17mm |

| Pipe outer diameter | Φ20-85mm |

| Fin pitch | 0.6-10mm |

| Pipe Max length | <20m |

| Packaging | Wooden case |

| Power supply | 380/50-60hz |

Tube finning machine features

- At the bottom of this machine, there is a coolant storage tank. The coolant is cooled through a hose and then transferred to the roller mold. A hose-clamping machine has professionally processed this hose.

- The roller mold has three triangular arrangements, and triangles are known to be the most stable combination, so this fin tube machine can smoothly output mighty power.

- A set of roller molds can produce fin tubes of various diameters, and this multi-size application design saves the owner a lot of investment funds.

- There is a scale for adjusting the screw position of the tube finning machine roller mold, with a maximum accuracy of 0.1mm. Engineers can observe this scale to accurately adjust the diameter size of the pipe and improve work efficiency.

- We accept customized appearance color services for fin machines, but a machine can only have a maximum of two colors.

The tube finning machine working video

Installation precautions

1. Sufficient space needs to be reserved on both sides of the machine for pipeline movement; otherwise, the device cannot usually be used.

2. For more accessible sea transportation, we need to drain the oil from the gearbox and add gear oil before starting up and running.

3. If the installation of the machine is not smooth enough, do not start running it

4. This machine needs to connect to a 380V three-phase power supply,

5. The first time running the tube finning machine, it is necessary to check the direction of the motor. If the motor is running in the opposite direction, two wires need to be exchange

6, Fin tube compression generates heat, and ordinary coolants cannot meet production needs. A high-quality coolant must be in the bottom groove.

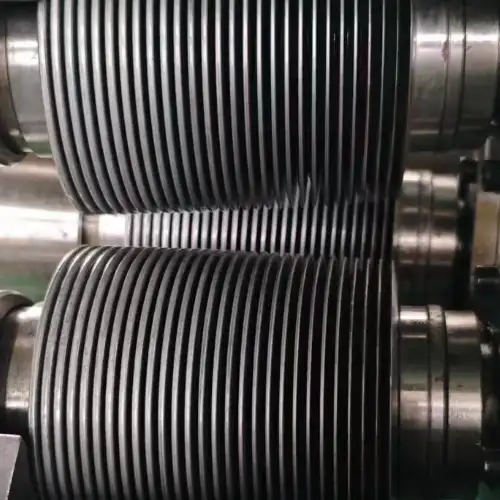

Tube finning machine roller mold

This roller mold comprises multiple circular blades made of special steel, which are then to high-temperature quenching treatment to ensure their wear resistance and service life.

Because aluminum tubes are extruding during the fins’ production process,

the size of each blade of the roller mold is scientifically calculated and then combined and arranged to ensure that each blade is evenly stressed.

A set of roller molds consists of three sets of blades, each with an independent number that is laser engraved and permanently attached to the blade. These numbers are essential when the tube fin machine changes the mold.

wechat

wechat