Machine Overview

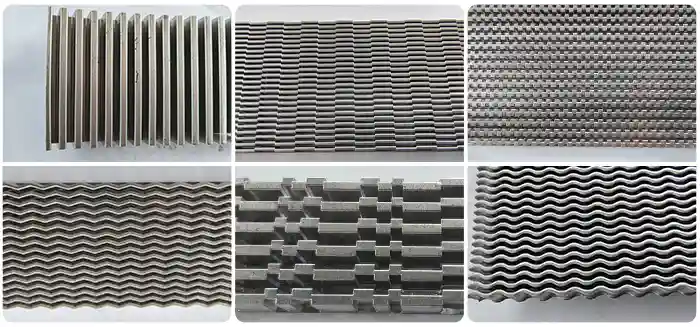

This inner fin machine can produce various high-precision fins, such as window fins and wavy fins, for evaporators, oil coolers, and bar heat exchangers.

The equipment has a PLC touchscreen control system that can achieve visual operation. The inner fin machine’s operation is effortless, and it can produce various high-precision fins. The machine runs stably, and the mold is replaced quickly.

This machine can produce various raw metal materials, such as aluminum foil, copper foil, iron foil, stainless steel foil, titanium alloy foil, etc.

Through the unremitting efforts of our engineers, they continue to improve and optimize our internal fin machine. Currently, the machine can be fully automated, and unattended production

Why Choose Our Inner Fin Machines

Our machines are far superior in quality to our competitors

We manufacture high-quality machines while also taking into account very competitive prices

Customize your fin, and we can design and manufacture any fin mold based on your fin

Fully automatic fin production machines. Currently, no other company can achieve the production of fully automatic machines except us

Fast delivery: our warehouse has long-term inventory. If you do not have customized molds, our fastest delivery time only needs 2 weeks

Other fin machines

Condenser fin mold and Progressive die

Product Introduction The condenser fin mold is a tool for continuous high-speed production. It is a fully auto progressive mold tool that combines multiple molds with different functions. This mold is the main production tool…

Fin roller machine | condenser fin machine

Machine Overview the radiator fin roller machine is the key machine for processing condensers, radiators, and intercoolers; its total power is 3.5kw. The fin roller mold is made with high precision. The servo motor counting…

Fin stamping machine of condenser and heat exchanger

Machine Overview The high-speed fin stamping machine produces heat exchanger and condenser fin parts. It can reach a maximum speed of 280 times per minute, currently the highest level in the stamping machine industry. This…

Fin progressive die of heat exchanger

Mold Overview 1. This fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc. 2. It is suitable for aluminum foil with different states and thicknesses at home and…

Q & A

A: We have this machine in stock. If you need to customize this machine, the delivery time is approximately 65 days.

A: Yes, we have a CE certificate for this machine

A: No problem. If you don’t need inventory machines, you can choose any color machine

wechat

wechat