Product Introduction

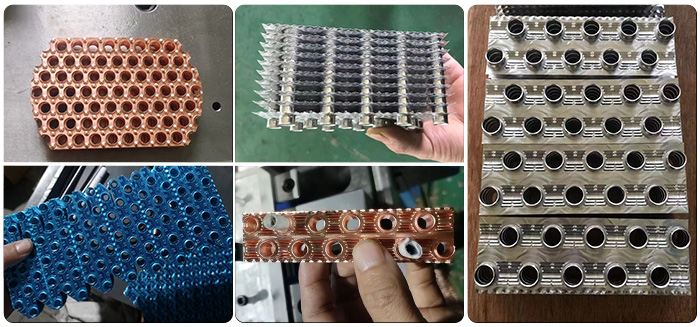

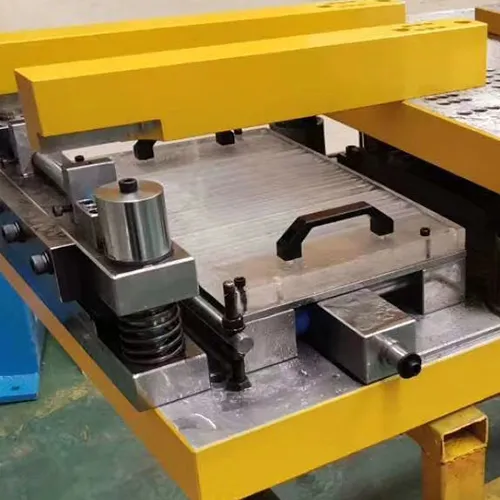

The condenser fin mold is a tool for continuous high-speed production. It is a fully auto progressive mold tool that combines multiple molds with different functions. This mold is the main production tool in modern heat exchanger factories.

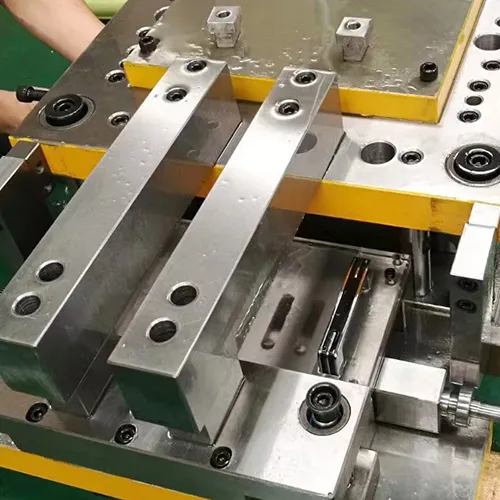

The metal material of the fin pressing mold parts is high-speed wear-resistant steel, SKH51, SKH11, which has undergone vacuum high-temperature quenching treatment to extend its service life.

The key components of the fin mold are design to be replaceable. The fin’s size cannot meet the design requirements if the parts wear out during long-term high-speed use. Only low-cost replacement of the key components of the mold is needs

Condenser fin mold material details

Condenser fin mold features

1. Fully adapted to the characteristics of highly automated production, the entire production process does not require worker intervention.

2. The key components are independent, which allows for low-cost replacement of these parts, extending the mold’s use indefinitely and reducing the factory’s operating costs.

3. Reasonable geometric layout: One layout cutting knife and the other layout are almost zero cost so that it can produce condensers and heat exchangers with different heat transfer efficiencies and sizes.

4. The condenser fin die has multiple lubricating oil tubes to the stamping machine for synchronous lubrication

Why choose our fin mold

The perfect solution

Customize this fin mold based on your fin design and production output to meet the production needs of your condenser and heat exchanger.

Efficient delivery

89% of the mold parts in our factory are produc in the workshop, and each process is scientifically design to improve efficiency, simplify unnecessary steps, and enhance work efficiency.

Innovative technology

We have been deeply involved in this industry for years, maintaining continuous innovation and providing advanced solutions for manufacturing heat exchangers and condensers.

Reliable quality and service life

The key components of the fin pressing mold are CNC making and ground to ensure their smoothness and accuracy, extending the mold’s service life.

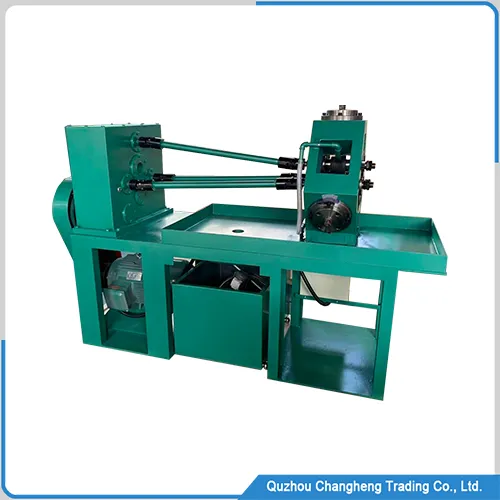

Condenser fin mold factory video

Installation precautions

This mold can be on 90% of stamping machines on the market, but we must reserve installation holes based on your stamping machine.

Our molds can handle high-speed production, but they are also compatible with stamping machines for low-speed production.

Due to the large mold size, weighing approximately 600-800 kilograms, It is necessary to replace the mold with a forklift.

During high-speed production, the stamping mold for the condenser needs to connect to compressed air to allow waste to fall smoothly.

Q & A

A: Yes, We accept all sizes of customized molds.

A: Our mold delivery time is 55-65 days

A: It is a wooden crate that meets international logistics standards

wechat

wechat