Product Description

The aluminum expanded radiator production line is composed of multiple machines. One machine is complete and essential work, and another machine needs a worker. Our company customizes these machines. Usually, these machines are not available in the market

Aluminum expanded radiator production line characteristics

The fastest production speed of a fin stamping machine is 300 times per minute, which adopts a forced lubrication system to prevent wear;

The installation height of the mold can be adjusted electrically, and the size is very accurate. A combined pneumatic friction clutch brake ensures smooth engagement and sensitive action. It also has an overload protection system, and the machine has an uncoiler, oil tank, J-type table storage, and aluminum device

Crimping machine for the plastic radiator tank, which is driven by a servo motor and cylinder

Touch screen human-computer interaction system. According to the different shapes of plastic tanks, simple programming machines will automatically avoid obstacles

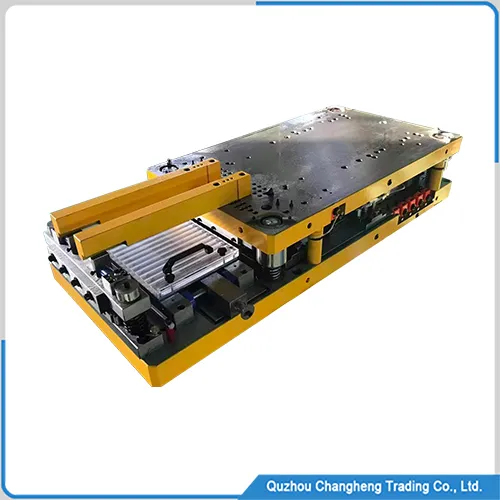

The horizontal expansion machine is hydraulically driven. It has a PLC control system. The aluminum tube oil is automatically injected. Only the aluminum core needs to be put into the machine manually. The machine automatically completes other steps

We can also design servo-driven machines for customers. The price of servo-driven machines will be a little expensive

production line display

Why choose our aluminum expanded radiator production line

Q & A

A: The fin machine is packing buy wooden cases. We’ll employ horizontal packaging machines to make it simple to place containers.

A: Yes, it is better to buy a screw-type air compressor, about 15-22kw

A: Our delivery period for this customized complete machine is 75 days.

A: Yes, we can supply all the raw materials

A: If it is a factory in China, it needs about 8-10 people

wechat

wechat