Product Description

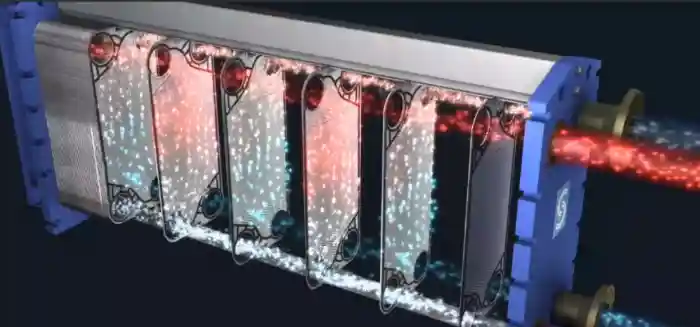

This type of plate and frame heat exchanger is a device that transfers heat between two different media. It is assembled with multiple different parts to form a complete heat exchanger and has a wide range of applications in modern industry.

Usually, a heat exchanger has two independent channels and two types of media flow in their respective channels to achieve heat exchange,

To achieve the best heat transfer efficiency, the design of the channel will increase ripples, and the flow of liquid in the channel will generate turbulence, thereby increasing the heat transfer coefficient to a higher level

characteristic of plate and frame heat exchanger

Efficient and energy-saving:

Thanks to its excellent design, it has increased efficiency by 3-5 times compared to tube and shell heat exchangers

Compact structure:

It has efficient heat exchange efficiency, so its structure is relatively compact

Easy to clean:

Plate and frame heat exchangers use bolts to lock the frame for easy opening and cleaning of the interior

Strong adaptability:

Its unique structural design allows for the addition or reduction of channel plates at will, changing the heat transfer efficiency to meet different application scenarios

Reliable design:

The channels of the plate heat exchanger are scientifically designed and sealed with gaskets to prevent the cross-flow of liquids. If there is a leak, the hot and cold liquids will always be discharged outward and will not mix.

Plate and frame heat exchanger factory video

Other heat exchangers

Industrial heat exchanger of shell and tube type

Product Description This industrial heat exchanger is of the tube and shell type and is one of the most popular devices in modern production. In many industries, it is necessary to regulate the temperature of…

Shell and tube heat exchanger

Overview The shell and tube heat exchanger adopts a cylindrical shell with uniformly arranged tube bundles inside, assembled in a sealed manner to allow two different media to exchange heat. This structural design helps to…

Plate heat exchanger for selling

Product Description This plate heat exchanger type is one of the most popular, consisting of many stacked metal plates. The edges of the metal plates are sealed with EPDM gaskets, and both ends are reinforced…

Application area

- textile industry

- paper industry

- Central heating

- Thermal power plant

- Boiler heating

- Oil and fat industry

- electric power industry

- Marine diesel engine

- Solar energy utilization

- chemical industry

- steel industry

- Metallurgical industry

- Machinery manufacturing industry

- food industry

- Beer production

- Central cooler

- Seawater desalination

Plate and frame heat exchanger data

| Part Name | Raw Material |

| Flat plate | SS304 Titanium alloy |

| Frame | Ordinary carbon steel |

| Sealing strip | EPDM |

| Screw | Stainless steel |

| Nut | Stainless steel |

| Maximum pressure | 1.8 mPa |

| Packaging | Wooden box |

Our competitive advantage

1, Our heat exchanger factory has a 300-ton stamping machine that can press and produce metal plate parts of any size

2, We produce the plates and frames of the heat exchanger ourselves, effectively controlling costs and providing customers with more competitive prices

3, Our factory has 18 years of experience and experienced engineers. No matter what size of heat exchanger you have, we can provide excellent solutions

4, In addition to plate and frame-type heat exchangers, we also offer production tube and shell-type heat exchangers.

5, If you manufacture plate heat exchangers, we can provide you with various metal plates of different sizes that you can easily assemble in your factory.

Q & A

A: The usual delivery time is 30 days, while the delivery time for large-sized heat exchangers is 45 days.

A: Of course. We have many stamping molds that can produce various sizes. For more details, you can contact our engineers.

A: We strictly follow China’s mandatory service policy, and the guarantee period for this heat exchanger is one year

wechat

wechat