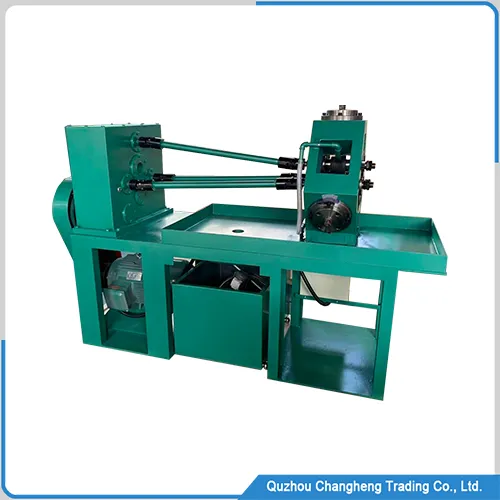

Machine Overview

The tube fin machine is a device applied in the field of heat exchangers, which mainly squeezes metal pipes into the shape of thin fins, allowing the entire pipe to have good heat dissipation ability,

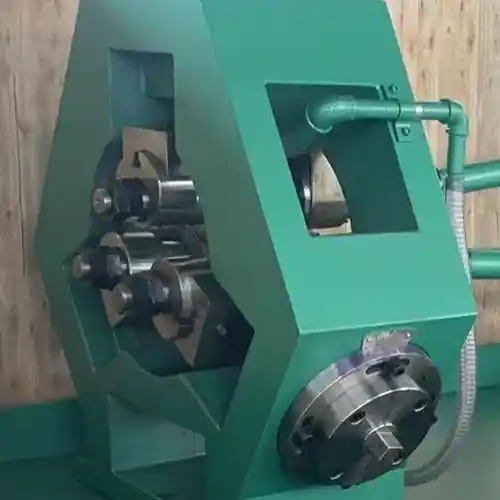

This machine uses an electric motor as the main driving force, which increases power through multiple sets of gears and drives three sets of rollers to squeeze and produce fin tubes simultaneously

The machine has many advantages, such as reasonable structural design, a simple control system, and the ability to produce various fin tubes of different diameters without additional cost, which have been widely recognized in the market

Types of tube fin machines

1, Two metal fin tube equipment

This machine produces two metal fin tubes, an inner tube made of iron or stainless steel material and an outer fin made of aluminum or copper. It has multiple tubes that can be freely combined

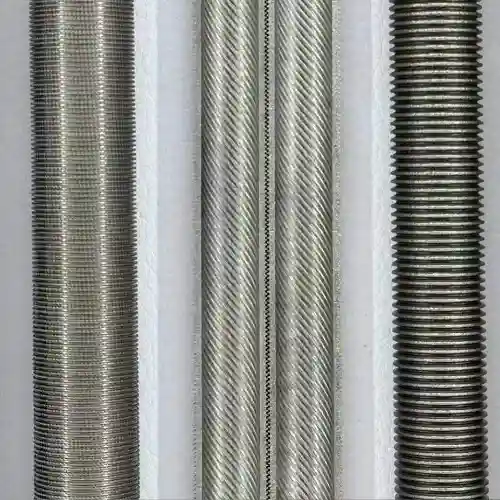

2, low fin tube machine

This type of machine produces low-fin tubes, usually made of single metal materials such as iron, copper, aluminum, etc. Due to the special characteristics of this type of fin pipe, the production speed of the modified machine will be relatively slower

3, Spiral tube machine

This type of machine squeezes seamless pipes into a spiral shape, and liquid flows from the inside of the pipes to form vortices,

Previously, this type of pipe was produced using a lathe, which had low production efficiency and high production costs. Now, the extrusion pipe fin machine has effectively solved these problems

4, Fin winding machine

This machine spirals aluminum foil around a pipe; theoretically, it can produce infinite-length pipes with simple adjustments to produce fin pipes of different diameters, but the minimum pipe diameter cannot be less than 12 mm.

The device has many advantages, such as a compact body, the ability to produce multiple sizes, no need for welding, etc., and has a high market share.

Tube Fin Machine Parameters

| No. | ITEM | DATA |

| 1 | Fin material | aluminum copper |

| 2 | Base tube material | SS304 aluminum copper alloy, etc. |

| 3 | fin material thickness | 0.2-0.4mm |

| 4 | tube diameter range | 10-38mm 8-51mm |

| 5 | Fin height | less than 17mm |

| 6 | Fin pitch | 0.6-2mm 1.6-10mm |

| 7 | tube outer diameter | Φ25-88mm |

| 8 | tube Max length | 6-20m |

| 9 | Packaging size | 224*85*145cm |

| 10 | G.W | 1480kg |

Repairs and maintenance

The structural design of this pipe fin machine has been optimized multiple times and does not require expensive maintenance costs during normal use. Cleaning the debris on the coolant isolation net only requires cleaning it and adding lubricating oil to each universal joint. This simple maintenance work can ensure the smooth operation of the equipment.

This machine uses three sets of rollers to squeeze fin tubes, which can generate high temperatures quickly. Therefore, coolant is required. Due to the long-term circulation of coolant, its components will be diluted. You need to add high-concentration coolant or replace it regularly.

wechat

wechat