Product Introduction

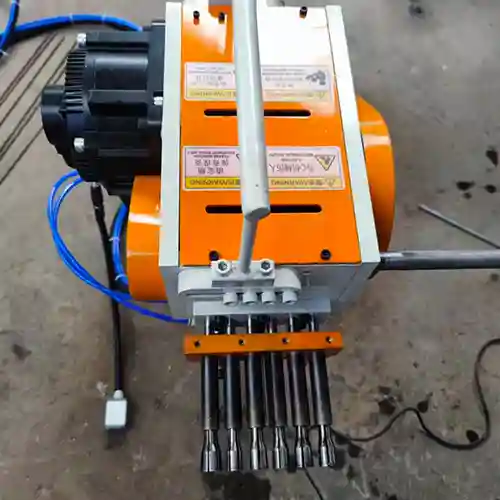

The flexible tube expander machine is a servo motor-driven device that produces large heat exchangers and condensers.

The machine has a 7.5kw servo motor that outputs mighty power through 10 times gear conversion. It can expand almost all soft metal pipes.

No matter what metal material your heat exchanger tubes are made of, this expansion machine can easily complete its work and meet your production needs.

Flexible tube expander Machine advantages

Silent production and power-saving

The primary power source of this machine is the servo motor, which does not produce noise during the production process, making it very friendly to the factory environment,

Due to servo motors’ special nature, power saving is one of their characteristics. When the device briefly stops, the motor does not run, so it does not consume electricity.

The intelligent control system.

The touch screen has multiple languages for users to choose from, and we accept customization in any language on the touch screen,

The touch screen allows users to pre-set the size and specifications of the heat exchanger, as well as the expansion speed and output settings. This multifunctional setting can increase the user experience.

The expansion machine’s control cabinet has reserved output ports, allowing users to connect other devices to experience linkage production or upgrade the equipment in the future.

Simple post-maintenance

The design of this flexible tube expansion machine is very reasonable. It does not require any maintenance or upkeep during normal production and use. If the machine is temporarily in use, the expansion rod must be lubricated with oil.

Flexible use of multiple sizes

Various fins with different geometric arrangements are usually produced in heat exchanger factories. To address the practicality of changing molds with multiple sizes, we have designed a quick exchange module for this equipment,

Engineers can quickly replace modules according to size requirements to adapt to diverse production needs.

Tube expander machine quick details

| ITEM | DATA |

| Starting speed | 5 second |

| Expansion speed | 10-30 meters/min |

| Return speed | 25 meters/m |

| Expansion length | 0.5-15m |

| Pipe diameter | customized |

| Workstation | 2 / 4 / 6 / 8 optional |

| Touch screen | 7 inches |

Flexible tube expander Work steps

1. Place the core of the condenser flat on the table and organize the fins of the core to meet the expansion requirements

2. Hang the flexible tube expansion machine on the balance sliding device and install it on the gantry frame

3. Start the start button of the machine; the machine starts working and set the production type to automatic mode

4. Align the tools on the flexible tube expansion machine with the copper pipes of the condenser, press the green button on the machine, and the machine will automatically complete a series of actions

5. Repeat the fourth step until all copper tubes are expanded and a complete condenser core is produced

Technical Parameter

- Power supply: 3-phase/308v

- Voltage: 5.5kw

- Touch screen brand: Shenzhen, China

- Delivery time: 45 days

- Appearance color: customized

- Servo motor brand: Delta

- PLC brand: Mitsubishi

Flexible tube expander Display video

Other heat exchanger machines

Side plate fixing machine of expanded radiator

Side plate fixing machine Structure the Side plate fixing machine mainly produces round tube radiators…

Tube expanding machine for Industrial heat exchanger

Product Description The Tube expanding machine is the latest equipment driven by servo motors. The…

Tube straightening machine

Machine Overview The Tube straightening machine is a production equipment for heat exchangers, which is…

Flaring machine For mechanical radiator

Purpose of equipment: radiator flaring machine for All aluminum radiators and expansion machines for warm…

Installation precautions

1. Because the servo motor adopts the most advanced control technology, the machine’s touch screen will display an alarm on the first installation. Engineers need to follow the instructions to set the driver’s parameters strictly.

2. When you use this flexible tube expander machine to expand titanium alloy and stainless steel metal pipes, lubricating oil needs to add the inside of the pipes.

3. The machine needs multiple production work modes, which do not require frequent switching of work modes. Only the most suitable one needs to be selected.

4. The volume of the expander is small, but sufficient space needs to be reserv according to the size of the heat exchanger for the expansion position of the expansion rod

wechat

wechat