Production line overview

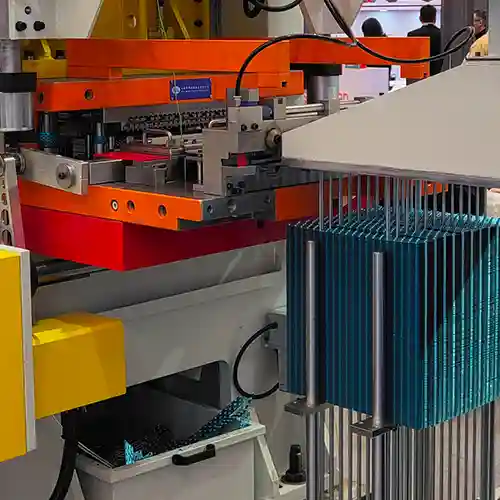

The High-speed Heat exchanger fin production line is a special cast iron alloy with high rigidity and shock resistance. The slider is designed with a long guide circuit and equipped with a slider balance device to ensure the precision and stability of operation.

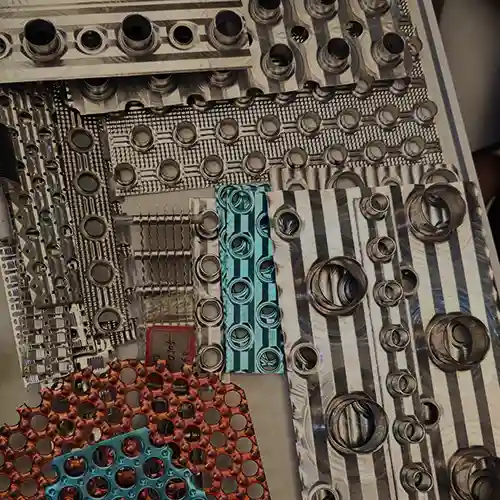

The high-speed heat exchanger fin production line is an automated production equipment used to manufacture high-speed heat exchanger fins. This machine typically consists of multiple independent parts used to form fin shapes on metal foil.

In order to ensure the efficient operation and precise control of the production line, the machine has been equipped with an electronic timing automatic lubrication system. This system automatically provides lubricating oil for the anti-wear components in the press to ensure the normal operation of the components and extend their service life.

Meanwhile, the control system is a key component of the high-speed heat exchanger fin production line. Advanced control systems can ensure the accuracy of slider operation and stop, thereby achieving efficient production. At the same time, the control system can also meet various automated production needs, such as automatic monitoring of equipment status, automatic adjustment of production parameters, etc.

The high-speed heat exchanger fin production line is usually used in the production of precision components such as household air conditioning condensers, automotive radiators, industrial heat exchangers, and motor rotors, which can greatly improve production efficiency and reduce production costs.

Fin production line technical data

| ITEM | VALUE |

| Control | PLC |

| Lubricating oil | automatic lubrication |

| Machine appearance | custom colors |

| Voltage | 5.5kw |

| Machine parts | Oil tank Aluminum foil feeder Stamping machine Fin storage machine |

| Origin | China |

| ITEMS | DATA |

| Die Height Adjustment | Motorised |

| machine name | fin production line |

| Crank Bearing Way | Roller Bearing |

| Angle Display | Pilot Pin Digital Mode |

| Signal Output | Rotary Encoder |

| Main Motor Power | 5.5kw |

| fin mold Height | 200~270mm |

| Capacity | 450 KN |

| Stroke | 150~250 S. P. M |

| Width of Material | 300mm |

Our success stories

fin production line video

Q & A

A: Our production line machines are packed in wooden cases. In order to smoothly load the machines into containers, we pack the machines lying down.

A: The punching force of this machine is 45 tons, and the production speed is 300 times per minute. Your factory floor needs to be reinforced, It can only be produced on the first floor

A: The fastest production speed of this machine is 300 times per minute.

wechat

wechat