Machine Overview

The tube straightening machine is an automated equipment in the heat exchanger industry. It integrates the functions of feeding, straightening, cutting, and storing metal tubes. It has six independent workstations, each of which can handle different tube diameters, and supports cutting requirements of any length.

This equipment uses servo motor closed-loop control, and the length error of each tube will not exceed 0.1mm. It also adopts roller chip-free cutting technology, and the cut surface has a 0.5mm circular arc. The roughness is controlled within Ra1.6μm.

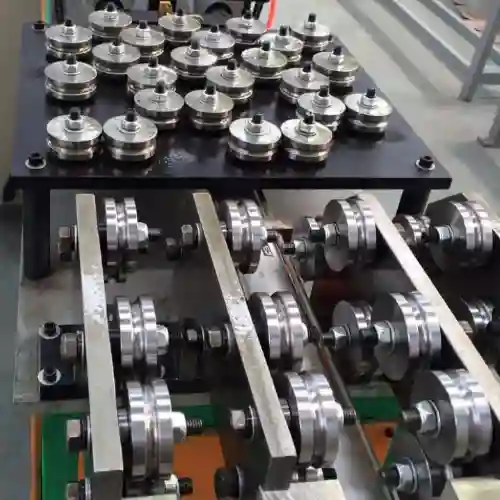

The straightening module uses a multi-group roller layout, which can perform three-dimensional tube correction. The straightness error of a 1000mm metal tube will not exceed 0.5mm.

Tube straightening machine Characteristics

Coordinate work in multiple workstations

This machine has multiple workstations; each workstation can produce different tube sizes. Users can choose a machine with 4-8 workstations according to production output requirements.

Dust-free cutting technology

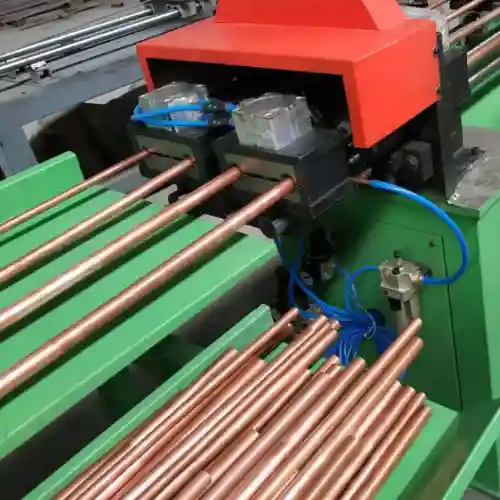

By combining complex tools and high rotation speed, as well as the cold cutting process, we can achieve tube cutting without burrs, and without any material waste. The cutting edge has a 0.5mm radius. This process makes it easy to insert the copper tube smoothly into the hole in the fin.

Precise control

The Tube straightening machine uses Delta servo motors to move the copper tubes, and with the control of absolute value encoders, it can achieve an accuracy of ±0.1mm. Compared with machines driven by stepper motors and cylinders, it significantly increases the accuracy and production speed.

Intelligent human-computer interaction

The control unit uses a PLC and a 7-inch touchscreen. It has built-in multiple production modes for one-click switching. The length of the tube and the production speed are set through the touchscreen. If the machine has any faults, the screen will display the code, and the engineer can easily correct the error.

Tube Straightening Machine Technical Parameter

| ITEM | DATA |

| Control system | PLC touch screen |

| Main drives | servo motor pneumatic |

| Programmable | Yes |

| Pipe material | aluminum copper |

| Pipe diameter | 5-20mm |

| Workstation | 4-8 PCS customized |

| Pipe length | 100-3000mm |

Tube straightening machine production steps

- Prepare the materials.

There are two types of coil copper tubing materials: the tube from the inside to the outside, and the tube from the outside to the inside. Our machine is compatible with both types. One is to lay it flat on the ground, and the other is to place the material on the rack, then extend the tube to the position of the straightening wheel.

- Multidirectional straightening.

The copper tube goes through multiple sets of straightening rollers, undergoing straightening from top to bottom and from left to right. The grooves of the rollers and the outer diameter of the tube fit together and rotate, forcibly eliminating the stress of the tube to make it vertical.

- Feed control

The cylinder tightens the tool to lock the copper pipe, and then the servo motor drives the ball screw to move through the speed reducer. The distance moved is the length set by the touchscreen. If the length of the tube is greater than 1.5 meters, the Tube straightening machine will intelligently calculate multiple movements to ensure that the size meets the set value.

- Dust-free cutting.

The cutting unit consists of three small rollers, with a triangular arrangement of copper tubes in the middle. The motor drives the three rollers to rotate simultaneously at high speed, and then the cylinder presses the blade to perform chip-free cutting.

- Collect tubes.

After cutting, the tube automatically slides into the material bin, 1.5m long. Expanding it can collect 3-5 meters of copper tubing. At this point, the production of one tube in the copper tube straightening machine is completed. You can check the video below to understand the entire production process.

The application scenarios of the Tube straightening machine

This machine is designed for the heat exchanger industry to process copper tubes for condensers and evaporators. It can handle tubes with a diameter of 7-25.4mm. Thanks to the smooth power output of the servo motor, it can automatically adapt to metal tubes with a wall thickness of 0.15-0.5mm.

Moreover, this machine will not cause any damage to the surface and inner wall of the tube during the straightening process. Therefore, this machine is also need to straighten and cut metal tubes in some high-precision manufacturing industries.

The roller cutting technology of this machine is compatible with both copper pipes and aluminum tubes, so its scope of use has been dramatically expanded, such as in the pipelines of the air conditioning system in the automotive industry, and the aluminum tubes of heaters, etc.

If you’re looking for a metal tube cutting machine, click the button below for more details.

Our strengths

- Deep customization

We can customize this Tube straightening machine according to users’ requirements for the metal, production capacity, and tube diameter size. We can also increase the number of workstations from 4 to 10 for users. We can also provide options for the interactive language of the touchscreen and the color of the machine’s appearance, etc., offering a deeper level of customization services.

- Competitive price

The welding frame of this machine, the electrical control, and the parts made by CNC are all from our production, so our prices are very competitive, and the delivery time is also guaranteed.

- Longer after-sales service

Usually, the service policy of the Tube straightening machine is to repair it for 12 months. We have extended this time to 36 months. We provide free parts and online technical support if the equipment parts wear out during this period.

wechat

wechat