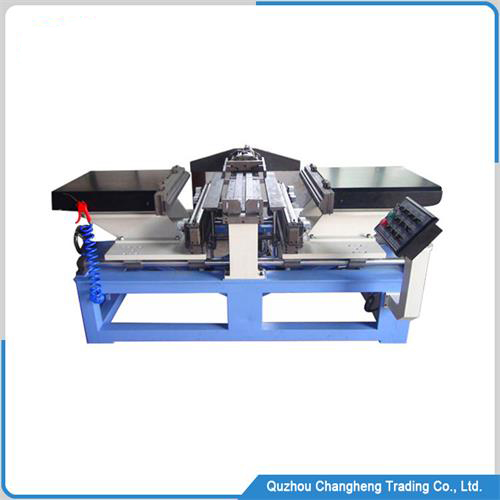

core builder machine outline

The Core Builder Machine is a fully automated car radiator core manufacturing machine that is assembled by aluminum fin machines, aluminum tube sorting machines, and core arrangement machines. Multiple independent machines are connected together to achieve efficient and fully automated production

Firstly, let’s take a look at the design of the Core Builder Machine. The design of this machine adopts a servo motor as the main drive, ensuring the high accuracy and stability of the machine.

At the same time, the design of the machine also takes into account the balance between production efficiency and manufacturing quality, allowing for the production of 60-80 radiator cores per hour.

In the control system of the machine, parts of famous brands such as Omron and Siemens are used. These parts have reliable quality and stable performance, which can ensure the high precision and efficiency of the machine.

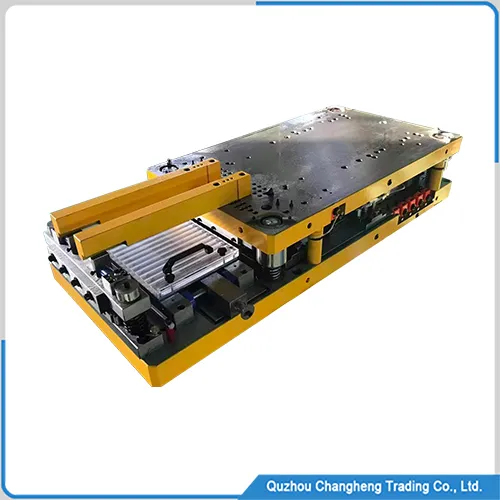

In addition, Core Builder Machine has designed modular fixtures and tools that can be customized for production according to different customer needs.

This modular tool not only improves production efficiency but also reduces production costs, while ensuring that the core quality of the produced radiator meets customer needs.

Technical Parameter

| ITEM | DATA |

| Fin machine speed | 300 meters |

| Core size | 300*300mm 120*120cm |

| Part appearance | nickel plated |

| Machine color | gray white |

| tube length | 300-1200mm |

| Motor brand | Delta Mitsubishi |

| Production rhythm | 60-80 pieces |

| Touch screen size | 15 inches |

core builder machine Production process

he Core Builder Machine is a fin machine that rolls aluminum foil into the fins of a radiator, automatically calculating and cutting the length of the fins based on the size of the radiator core. The aluminum fins will enter the designated position of the machine along a fixed track, and this process does not require worker supervision,

The pipe sorting machine completes the aluminum pipes of the radiator, allowing them to enter the designated position and alternate with the aluminum fins. When the machine reaches the required number of aluminum pipes and fins, the robotic arm will send them to the next step, which does not require worker supervision

When the aluminum tube and aluminum fin enter the designated position, the worker needs to place the head plate in the designated position of the machine. The servo motors on the left and right sides of the Core Builder Machine start working, and the head plate is installed on both sides of the radiator core

During the production process, the core assembly machine adopts a fully automated production process, thereby reducing manual errors and labor intensity. The machine can automatically complete the assembly of the radiator core, thereby improving production efficiency and manufacturing quality.

wechat

wechat