Mold Overview

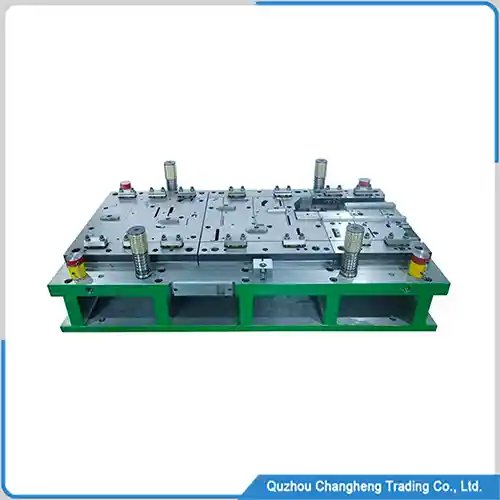

We provide a wide range of customized metal stamping mold services, specifically tailored to the needs of industrial applications. Our team is able to design and manufacture molds suitable for various stamping types based on the specific requirements of customers. We have professional technical capabilities and rich practical experience to provide you with the most suitable solutions, whether it is the need for continuous stamping molds to achieve mass production or the need for high-speed and precise fin progressive molds to meet high standards of machining accuracy. Our goal is to ensure the reliability, durability, and high efficiency of molds to meet your production needs and enhance your competitiveness.

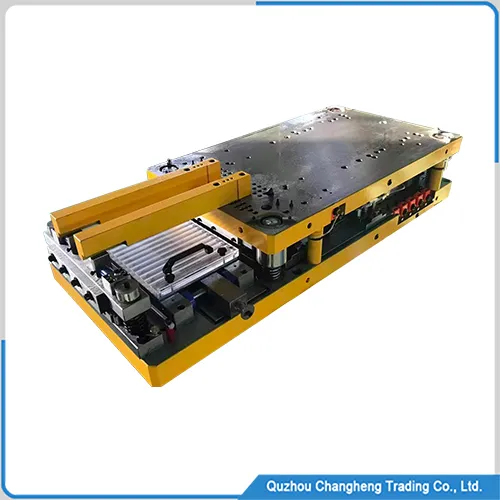

Our metal stamping mold

–These are our best-selling molds–

condenser fin mold and Progressive die

The condenser fin mold is a high-speed continuous production of die, this stamping die in the heat exchanger industry has a very wide range of use

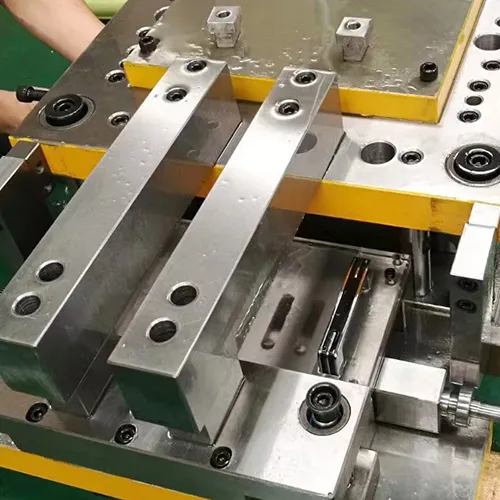

Fin progressive die of heat exchanger

This kind of fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc.

Why choose our stamping molds

–The advantages of metal stamping molds–

Easy to maintain:

A well-designed mold is easy to maintain and helps maintain production stability and continuity.

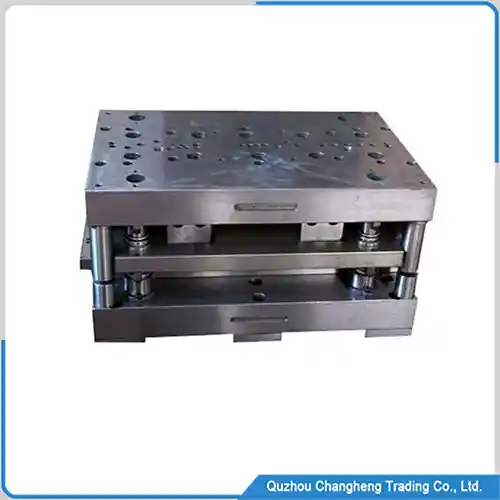

Durability:

High-quality stamping molds are made of wear-resistant materials and have a long service life

Customization:

Stamping molds can be customized according to the specific needs of customers, including different sizes, shapes, and functions, to meet special production requirements.

High precision:

Stamping molds can accurately manufacture the required parts, ensuring that the size and shape of the finished product meet strict tolerance requirements.

technical parameter of metal stamping mold

–For more details about the mold, please contact us–

| ITEM | DATA |

| Production: | Metal |

| Product: | Customized |

| Category: | Continuous,&Single |

| Guide pillars: | multiple |

| Application: | Industrial |

| ITEM | DATA |

| Board material: | RC12 & SK51 |

| work type: | Stamping |

| Needle brand: | LIDA |

| Color: | Green |

| Delivery time: | 45 days |

Metal stamping mold working video

–Contact us for more working videos on molds–

Q & A

A: Of course, this is our specialized field.

A: Need to provide samples of parts or D3 design.

A: Stamping molds usually take 300000 times or a year.

wechat

wechat