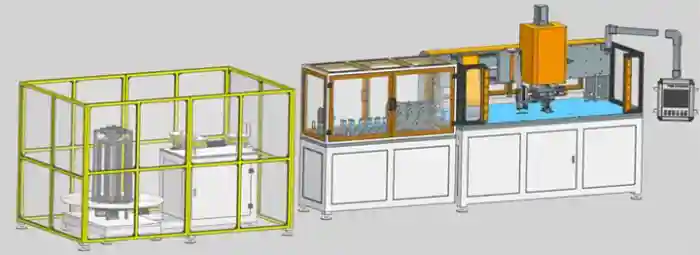

Machine outline

The Aluminum tube bending machine is a fully automated equipment that produces microchannel coil tubes through straightening, bending, necking, and cutting processes

Multiple servo motors drive this machine to control the length and bending angle of the microchannel aluminum precisely,

By changing different tools to bend various flat tubes for the production of automotive condensers and evaporators

production data can be directly save for easy and quick retrieval next time

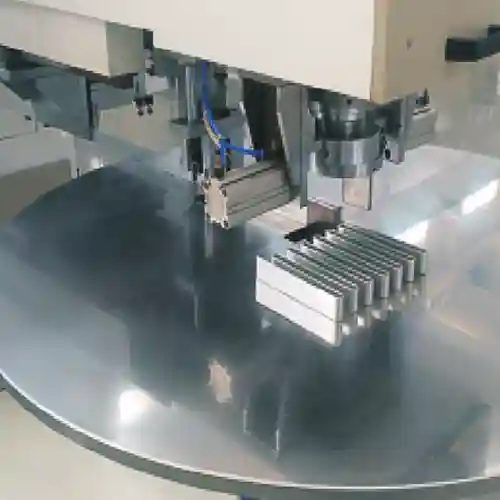

Aluminum tube bending machine productive process

1, Install the aluminum coil microchannel tube onto a dedicated rotating frame and secure it in place

2, Pass the aluminum microchannel flat tube through the straightening wheel device, and the machine will turn the coil tube into a straight tube. This bending equipment has upper and lower straightening pipes and left and right straightening pipes

3, Set the data for bending pipes, such as the length, quantity, and diameter of the pipes, and replace the bending tools if necessary

4, It is best to manually produce the first product that requires bending to verify the reliability of the machine

5, Set the pipe bending machine to automatic production mode, and the equipment will continue to produce fully automatically

Technical Data

| ITEM | DATA |

| Cutting | Automatic |

| Bending | Automatic |

| Weight: | 2. 5T |

| Production capacity | 20-30/min |

| Drive mode: | Servo+ Pneumatic |

| Overall Dimension: | 600*130* 170cm |

| Lubricating Way | full Automatic |

Native application

This device can be applied in automobiles, motorcycles, household air conditioners, and other fields. For example, the following products

- Automobile air conditioning condenser

- Automobile air conditioning evaporator

- Domestic natural gas water heaters

- Condensers and evaporators for pharmaceutical machinery

- Refrigerator evaporator

- Micro channel condenser

Aluminum tube bending machine working video

Q & A

A: The delivery time for this machine is 45 days. If you customize a special pipe type, it may take 55 days

A: All our machines are export in wooden cases

A: This machine is control by PLC and only needs to be set up. It can bend the pipe at any time.

wechat

wechat