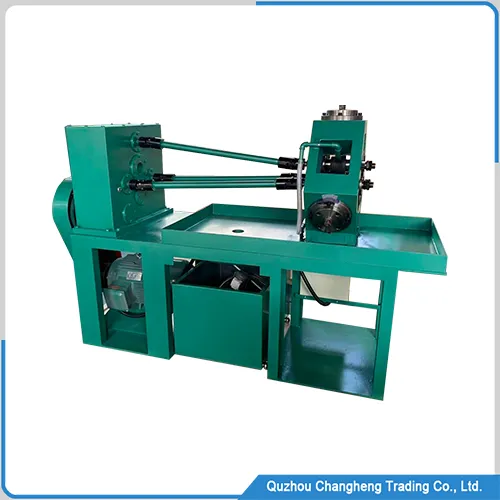

Machine Outline

The aluminum fin manufacturing machine is a production equipment for plate and bar heat exchangers. The market has always favored its compact body design, high operational stability, and reasonable price advantages.

Through the unremitting efforts of our engineers to continuously improve the machine, the fin machine has now achieved fully automatic production without needing a dedicated person to monitor the machine.

Our fin manufacturing machines are commonly use in automotive parts, marine cooling products, industrial air conditioning, engineering and mining machinery, engine coolers, aerospace, etc.

Fin manufacturing machine quick details

| item | data |

| Delivery time | 55 days |

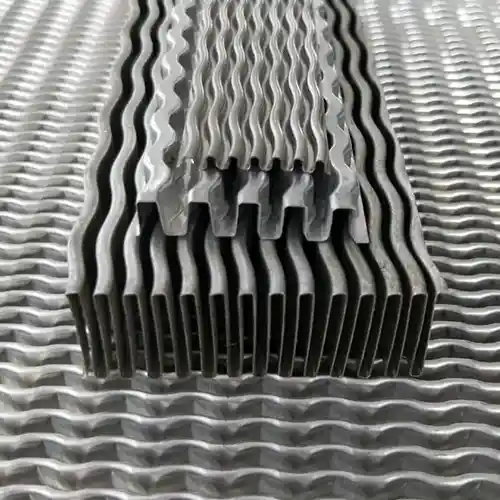

| Fin material | aluminum Titanium alloy copper stainless steel iron |

| Overall dimension | 135*75*165cm |

| Fin type | sawtooth wave parallel Dimple window shades ripple |

| Fin max width | 450mm 300mm |

| Packing | wooden case |

| Power supply | 380v/50Hz |

Fin manufacturing machine characteristic

- The main shaft of the fin machine is place in the center position, with uniform force on both sides, providing a smoother output of driving force during machine operation and effectively ensuring product quality.

- We have added limit devices to both sides of the high-precision mold workbench, greatly reducing the time for mold replacement and improving work efficiency.

- This fin manufacturing machine has a unique automatic lubrication system, and the lubricating oil can be recycled to reduce spindle wear and extend the service life of the equipment.

- The production speed of this device is advance continuously variable transmission, a breakthrough innovation that solves the problem of traditional equipment’s inability to adjust production speed smoothly.

- We have optimized the main structure of the machine and redesigned the mold holding platform. Now, only one person is need to easily install and debug the mold, making it easier to produce different types of fins.

Fin manufacturing machine working video

Advanced function of Fin machine

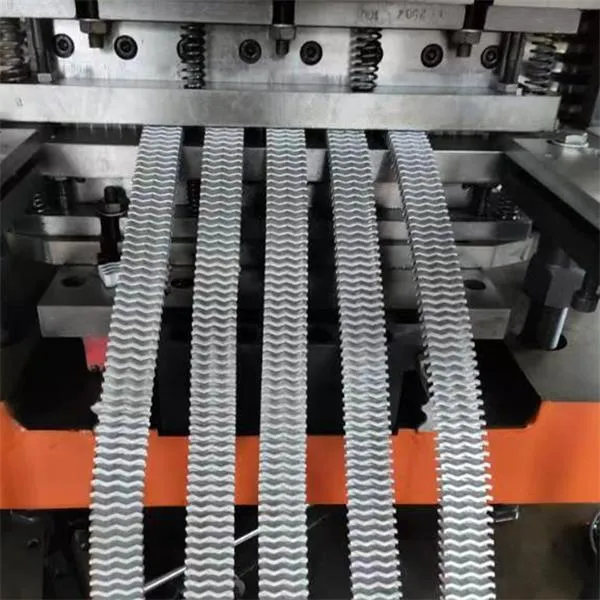

1. Our fin machine comes in two sizes, with a maximum size of 300mm and 450mm, respectively. It can automatically adapt to the fin width of different heat exchangers,

If the user produces fins with a width of 50mm, the 300mm fin machine can simultaneously produce 5 fins, which means a 5-fold increase in production efficiency without additional production costs.

2. The material lubrication device can adapt to any metal material, regardless of whether the user produces materials such as aluminum, copper, stainless steel, etc., and can be directly uses without tedious replacement work

The function of this device is to evenly adhere lubricating oil to the surface of the raw material, making it less prone to breakage and surface damage during the molding process

After-sales service policy

1. Our aluminum fin manufacturing machine has a warranty policy of up to 12 months, during which we provide free repairs for any equipment malfunctions.

2. Buyers of this fin machine can enjoy free installation and technical training services. Users only need to pay for our engineers’ airfare and hotel expenses.

3. We provide spare parts for the most easily damaged parts of the machine, which users can easily replace and extend the service life of the equipment.

4. We guarantee that users can use the device for up to 5 years. During this period, if any parts of the device wear out, we will provide them for free, and users only need to pay for the shipping cost of the parts.

wechat

wechat