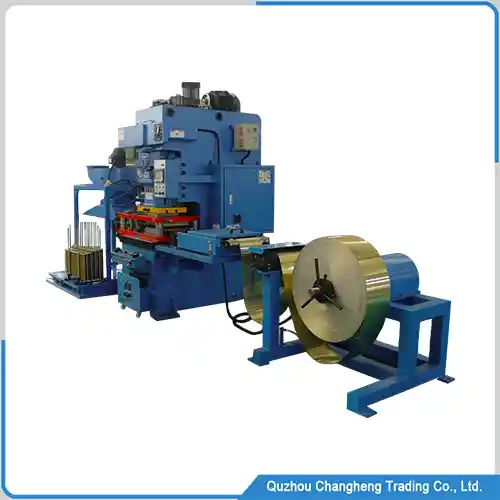

The Tube straightening machine is a machine specifically designed for straightening and cutting copper and aluminum coil tubes. In the heat exchanger industry, it is widely used and can efficiently complete the calibration and cutting of coil tubes. This equipment is already fully automatic and unmanned.

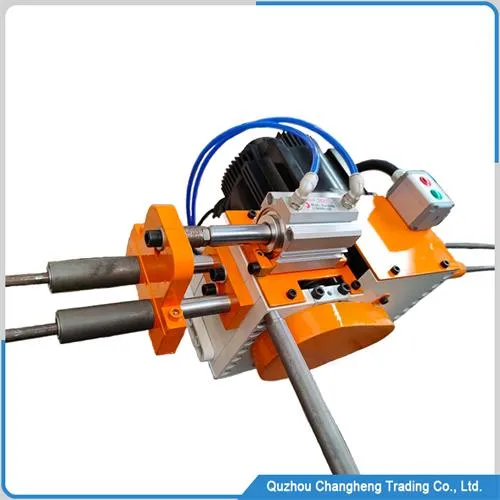

The working principle of the tube spacing machine is very simple. It has multiple sets of rollers arranged, and the coil tube is calibrated and straightened through the gap in the middle of the rollers. In addition, it is equipped with a cutting system that can accurately cut the coil through chip-free cutting technology.

Tube straightening machine Characteristics

1, The machine can be customized with 4-8 workstations or more, with different sizes designed for each workstation.

This allows for personalized customization based on customer needs to meet their different production needs

2, The machine uses a servo motor to drive screws, accurately controlling the length of each pipe. Customers can precisely control the length of pipes according to their own needs, thereby achieving higher production efficiency and better product quality.

3, The Tube straightening machine uses chip-free cutting technology to avoid the generation of chips during pipe cutting. This not only reduces the generation of waste but also saves a lot of production costs.

This technology can ensure that no chips are generated during pipe cutting, and there will be some shrinkage at the edges of the pipe.

Inserting the pipe into the fin hole of the heat exchanger will be smoother, thereby ensuring product quality and production efficiency.

4, The Tube straightening machine uses touch screen control to achieve automated control and real-time monitoring. Customers can control the operation status of the machine, control the length of pipes,

and set the production quantity through the touch screen. When the production quantity of the machine meets the set value, it will automatically stop

This technology can achieve real-time monitoring of production, and improve production efficiency and product quality, while also reducing employee workload and work pressure.

tube straightening machine Technical Parameter

| ITEM | DATA |

| Control system: | PLC touch screen |

| Main drives | servo motor pneumatic |

| Programmable | Yes |

| Pipe material | aluminum copper |

| Pipe diameter | 5-20mm |

| Workstation | 4-8 PCS customized |

| Pipe length | 100-3000mm |

summary

The tube straightening machine is a very important equipment in the field of heat exchangers, mainly used for straightening and cutting copper and aluminum coils

This machine has features such as customizable workstations, precise control of pipe length, chip-free cutting, and touchscreen control, which improve the accuracy and quality of pipes, production efficiency, and machine lifespan.

With the continuous development of the heat exchanger industry, the use of tube stiffening machines will become increasingly widespread.

wechat

wechat