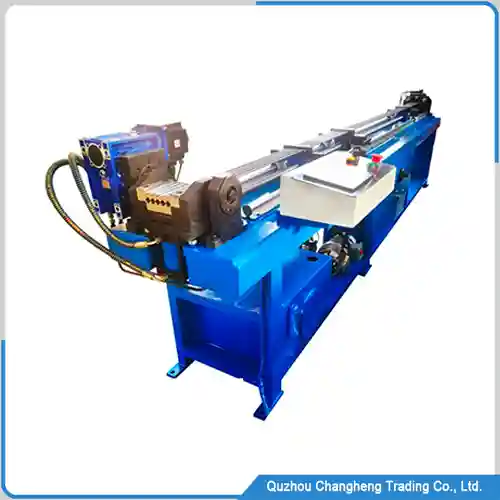

bender pipe machine outline

The Bender pipe machine is a device specifically designed to bend straight pipes into U-shaped pipes,

widely used in industries such as heat exchangers and condensers.

The equipment adopts hydraulic pressure as the main drive and is operated through a PLC control system,

which has the advantages of high efficiency, fast speed, and easy operation.

Usage process

When using the bending pipe machine for bending, the first step is to insert the pipe into the mold and ensure that it has been inserted into the specified position. Then, start the motor, and the bending tool will bend as needed. Usually, the machine only needs to run the bending tool once to achieve the desired shape.

During use, the bender pipe machine has the advantages of fast production, stable quality, and easy operation, which can improve production efficiency and reduce labor costs.

| ITEM | DATA |

| workstation | 2 / 4 / 6 / 8 / 12 Optional |

| Pipe diameter | 9.52mm / 12.5mm customized |

| Pipe length | 2500mm |

| Machine drive | hydraulic |

| Power Supply | 380v/50hz |

| Part brand | Mitsubishi Omron |

summary

This equipment has 2 workstations, 4 workstations, 6 workstations, and 8 workstations that are optional. Customers can choose the most suitable machine according to the factory’s production capacity requirements

We can also accept customized services for different pipe sizes to meet special application requirements

The use of bent pipe machines is very important for the development of the heat exchanger and condenser industry. It can improve production efficiency, reduce labor costs, and ensure high-quality bending shapes.

Therefore, the bender pipe machine has been widely used in the heat exchanger and condenser industry and will become an important trend in the future development of this field.

wechat

wechat