Product Introduction

Temperature recording instruments are important tools in modern industrial production, playing a crucial role in industries such as metal heat treatment, automotive parts manufacturing, chemical production, metal smelting, and aluminum brazing It adopts WiFi transmission technology to transmit the collected temperature data in real time to the computer, and displays the temperature curve on the computer screen. Engineers can quickly react based on this data to improve the production quality of the product.

This temperature recording instrument has 10 channels that can simultaneously collect data, and each channel can independently record data. Therefore, users can collect data from multiple locations inside the furnace for analysis. In addition, the instrument also has a data storage function, which can store up to 16 complete sets of temperature data storage.

It can be used in environments ranging from -40 ℃ to 1350 ℃ when paired with an insulated box. If you need this instrument to be immersed in water for use, we also have a waterproof insulated box to meet your needs.

Technical parameters of temperature recording instrument

- Product use: Temperature recording

- Product power consumption: ≤ 35mA

- Temperature channel: 2-12 pcs

- Battery: Lithium ion 950mA

- Collection rate: 0.05 seconds to 999.9 seconds

- Temperature gauge size: 140mm * 62mm * 20mm

- Measurement accuracy: ± 0.5 ℃

- Sensor accuracy: 0.3%

- Resolution: 0.1 ℃

- Testing method: continuous

- Maximum storage: 16 sets

- Maximum internal temperature: 80.0 ℃

- Start mode: Press the button to start

- Sensor: K-type thermocouple

- Measurement range: -40~1370 ℃

Advantages of temperature recording instrument

Two data transmission methods are optional

It has a built-in WiFi transmission module, which enables real-time data transmission with the computer. At the same time, it also stores data internally, effectively avoiding the risk of critical data loss.

Laboratory level measurement accuracy

Temperature data collection supports interval settings ranging from 0.05 seconds to 999 seconds. Users can freely set the collection time according to the characteristics of the product and production process, and the temperature accuracy is 0.5 ℃, ensuring smooth collection of even small temperature changes.

Modular design concept

This temperature recording instrument has a maximum of 10 channels and comes standard with 10 sets of thermocouple plugs. Users can freely expand to 4-10 channels to collect temperature data. It is almost used in various high-temperature heat treatment industries.

Replaceable lithium battery

This instrument is equipped with a 950Ah lithium battery with a voltage of 3.7V. It can work continuously for 24 hours in monitoring mode and supports battery replacement.

Temperature recording instrument working video

Software Analysis of temperature recording instrument

Using this software on a Windows 11 computer, it comes with two built-in languages: Chinese and English. When you run this software, the computer will automatically connect to the WiFi signal of the temperature instrument and receive data.

The software has multiple built-in file templates, making it convenient for users to quickly input PDF files or print files, achieving efficient work.

Through this temperature recording instrument software, users can observe changes in furnace temperature online, which is very helpful for production processes that require timely processing.

Engineers can modify and adjust the temperature curve themselves, add colors and label names to the curve, and users have 100% permission to customize secondary development and complete data reports.

The cursor on the computer can display temperature differences between multiple sets of temperatures at the same time, and can also compare multiple sets of temperature data, making it convenient for engineers to find the most suitable heat treatment process and improve product quality.

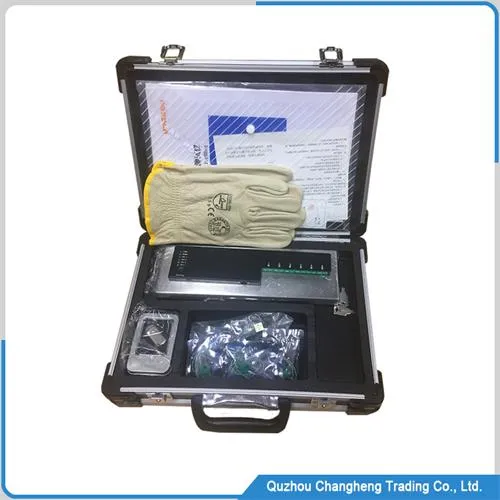

Insulated box of temperature recording instrument

1. The insulation box is an important accessory of the temperature acquisition instrument, which can ensure that the instrument works for a long time in a high temperature environment and records temperature data smoothly.

2. Usually, this insulation box is customized according to the user’s requirements. Due to different high temperatures and production processes, the size and appearance of the insulation box may vary.

3. Assuming the temperature environment is 620 ℃ and the temperature instrument needs to continuously record the temperature for 60 minutes, the size of this insulation box is approximately 400*300*280mm.

4. We accept customized services for boxes in any work environment. If you need insulated boxes to be placed in water, we also have waterproof boxes. If your temperature is 1350 ℃, we have a special steel insulated box to choose from.

Final summary

This temperature recording instrument is currently the most advanced equipment, with a small size but very powerful functions. In modern industrial heat treatment production processes, it plays an important role. Whether in industrial manufacturing, metal smelting, cooking, aerospace and other industries, it can perfectly complete various complex temperature recording tasks.

If you are looking for a temperature recording instrument to improve production efficiency or product quality, then our instrument is the best choice. If you would like to know more details about this instrument, you can send an email to our engineers Thank you very much for reading this.

wechat

wechat