Stamping Die Overview

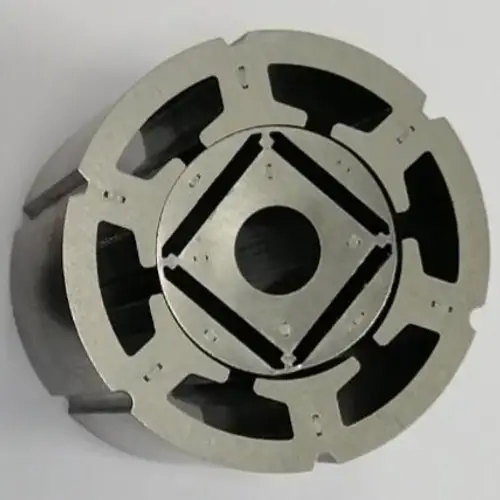

The motor lamination stamping die is an efficient production tool used to mass-produce iron cores in the motor production process.

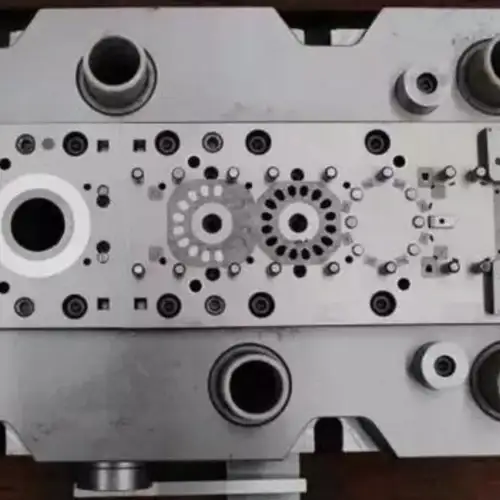

This type of stamping die is usually composed of multiple workstations, each performing specific stamping operations such as punching, forming, stacking, etc.

Stamping dies can operate continuously, improving production efficiency while ensuring product consistency and accuracy.

In producing motor cores, the motor lamination stamping dies can achieve automated production from raw materials to finished products, reduce manual intervention, and improve production efficiency and product quality.

Precise control of stamping parameters such as pressure, speed, and stroke can achieve the desired shape and size of the iron core.

Quality control

1, The height of the iron core can adjust according to the design requirements to adapt to the production of various motor products;

that is, as long as the diameter of the iron core is the same, it can produce iron cores of any height.

2, Each part of this motor laminating and stamping mold is producing using high-precision machine tools. This high-precision mold can adapt to high-speed production.

3, Use a three-coordinate measuring machine to inspect the iron core accurately, draw an accurate part design, and manufacture high-quality molds. Accurately drawing the design is a very important step.

4. The key feature of the stamping die is its replaceable design. When the die shows slight wear during long-term use, it can be easily replace at a low cost, prolonging its service life and ensuring the quality of the motor iron core.

5. To produce special rotors, a servo motor must install in the middle position of the mold to drive the laminating device and ensure the rotation angle.

This places higher demands on the mold’s accuracy. Therefore, our mold can perfectly solve this problem, and engineers can easily and freely control the rotation angle of the laminating.

Motor Lamination Stamping Die Data

| ITEM | DATA |

| Stacking type: | vertical, rotating |

| Production method: | fully automatic |

| Core parts: | rotor, stator |

| Workstation: | 1-5 optional |

| Rotary drive: | servo motor |

| Rotation angle: | free control |

| Iron foil thickness: | 0.2-1.5mm |

| Part diameter: | follow design |

Motor rotor Stamping Dies Video

Motor Lamination Stamping Die Advantage

1, High efficiency:

Continuous stamping can quickly complete the production of many iron cores, greatly improving production efficiency.

2, Consistency:

The automated production process reduces human error and ensures consistency in the size and shape of each iron core.

3, Save original and cost:

Due to precise design and efficient material utilization, production costs are effectively reduce.

4, Easy maintenance:

Stamping die design usually considers the quick replacement of vulnerable parts, reducing maintenance time and costs.

5, Strong adaptability:

The parameters of the stamping mold can be adjust according to the height of different rotors to adapt to the production of various products.

wechat

wechat