Product Overview

The Furnace tracker is a high-temperature testing tool that accurately collects temperature information inside the furnace, transmits it to the computer through WiFi signals, and records all temperature data of products inside the stove.

This temperature tracking instrument is vital in the industrial field as it can provide engineers with reliable temperature data and valuable data for continuous product improvement,

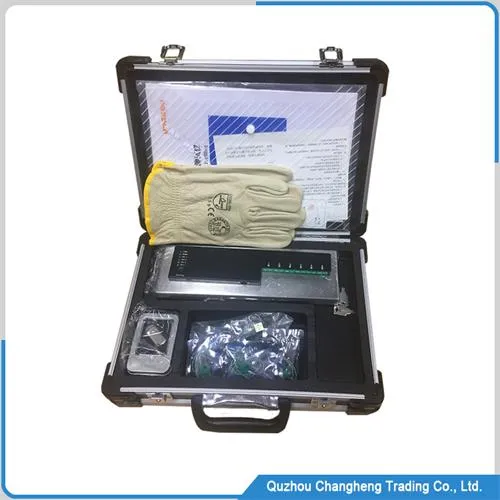

This temperature tracking instrument mainly consists of insulation boxes, thermocouples, temperature testing instruments, computer software, packaging boxes, etc.

Furnace tracker quick details

| No. | ITEM | DATA |

| 1 | Test Channel | 4/6/8/12 |

| 2 | Measure Range | -60℃~1370℃ |

| 3 | Thermocouple | K-Type |

| 4 | Precision | ±0.5℃ |

| 5 | Resolution | 0.1℃ |

| 6 | Sampling frequency | 0.05s~60 Min |

| 7 | Run Voltage | DC3.7V~DC4.2V |

| 8 | Battery | 1000mAh |

| 9 | Software | Including |

Furnace Tracker Features

The furnace temperature tester is key equipment used to monitor and record temperature data of industrial furnaces during heat treatment processes such as vacuum annealing,

powder metallurgy, spray painting, aluminum brazing, etc. Its main advantages include:

1, High-precision temperature measurement

The Furnace Tracker instrument can provide highly accurate temperature data, with a temperature error not exceeding 1℃

2, Data recording and analysis

It records temperature changes throughout the heating and cooling and generates detailed data reports.

Users can analyze this data to optimize heat treatment processes, improve production efficiency, and ensure product consistency.

3, Cost-effectiveness

The furnace temperature recording instrument helps optimize the heat treatment process, reduce energy consumption,

Avoid product waste and rework caused by improper temperature control, thus reducing production costs.

4, Real-time monitoring

The furnace tracker is connected to a computer through WIFI, allowing engineers to monitor temperature changes in real time and promptly detect and resolve abnormal situations

5, Compliance and Traceability

In many specialized industries, such as aerospace, automotive manufacturing, electronics etc., the heat treatment process must comply with strict quality standards and industry norms.

The data provided by the furnace tracker can serve as proof of compliance and facilitate traceability of the production process, ensuring quality control.

Furnace tracker working video

Furnace Tracker application

- Food industry: High-temperature drying of noodles

- Spray painting industry: temperature detection in paint baking rooms

- Metal smelting: precise control of furnace temperature

- Industrial production: precise temperature control of ovens

- Aluminum brazing: the importance of furnace temperature on products

- Brewing: Materials and distillation require temperature detection

Summary

This temperature testing instrument is widely used in various industrial production industries. It can collect temperature data from multiple channels and areas and check temperature changes online through WIFI transmission.

Our furnace temperature inspection instrument is a good choice if you want this type of instrument.

wechat

wechat