Product Introduction

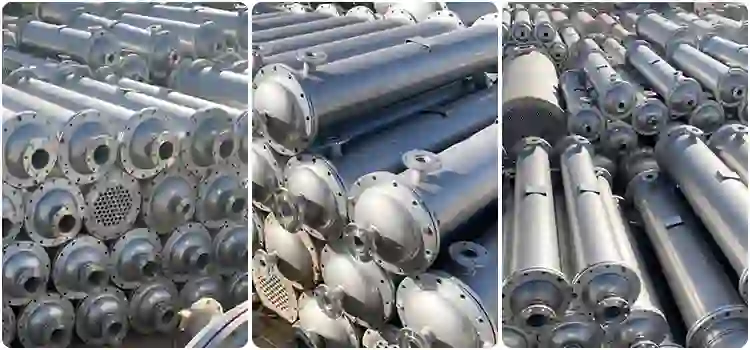

The Tube in tube heat exchanger has efficient heat transfer capabilities and a stable structural design. It plays a vital role in a wide range of applications, such as winemaking, chemistry, seawater desalination, and petroleum, which is currently one of the most popular heat exchangers in industrial production.

It utilizes a sturdy metal shell and components such as bundles and tube plates as its primary components, which enable stable heat exchange in high-pressure and high-temperature usage scenarios, and prevent the leakage of liquids or gases.

The almost zero-cost usage process is another advantage of this tube-in-tube heat exchanger. It has two independent cross channels inside, and the two media exchange heat through the metal thermal conductivity in the cross channels. This process does not require human participation, nor does it require the use of any electricity or energy.

The characteristics of the Tube in tube heat exchanger

Efficient heat transfer

Thanks to its unique internal structure design, the bundle tube’s exterior has been enhanced with threads to increase the heat dissipation area. Regardless of whether the medium is water, crude oil, steam, or beer, it can all exhibit efficient heat transfer capabilities and meet the strict requirements of the production process.

No need to worry about congestion

The internal bundle tube adopts a larger circular arc bending, and the inner diameter of the bundle tube is greater than 10mm. Even if the fluid contains suspended particles, there is no need to worry about internal blockage.

Wide adaptability

This Tube in tube heat exchanger can handle complex processes and a wide variety of fluid media in industries such as petroleum, chemistry, power, HVAC, and machinery.

The ability to cope with high pressure

Its shell is a relatively thick circular metal, and multiple high-strength screws connect the end cap and the shell. It can maintain a stable heat exchange efficiency at a maximum pressure of 4 MPa.

Technical parameters of Tube in tube heat exchanger

- Tube type: low fin tube or spiral tube

- Tube arrangement: hexagonal

- Connection method: screws and nuts

- Maximum pressure: 4 MPa

- Flange: CNC manufactured

- Fluid medium: water, oil, or other chemicals

- Heat exchange efficiency: Customized according to user requirements

- Installation method: horizontal or vertical

- Control method: valve

What are the materials of a heat exchanger?

The main components of this heat exchanger are the shell, end covers, tube sheets, flange connectors, and tube bundles. In various application scenarios, the materials used for these parts may differ, and we must also consider their lifespan, cost-effectiveness, and corrosion resistance, among other factors. Now, let me introduce the materials of these parts.

- Ordinary carbon steel

This is the most commonly used material, which is cost-effective and suitable for scenarios where the temperature is less than 350℃, and there are no corrosive fluids, such as cooling water and lubricating oil. Its corrosion resistance will be a bit worse.

- SS304/ SS304L

This is a universal material that exhibits good corrosion resistance and is suitable for use with cooling water, hot water, lubricating oil, steam, and other applications.

- SS316/ SS316L

This material exhibits significant chlorine resistance and is food-grade safe, making it widely used in the food, wine, beverage, and medical industries.

- Brass

As we all know, copper is one of the metals with the best thermal conductivity. In some industries that require high thermal conductivity, the material used for the tube bundle must be made of copper. Some heat exchangers have copper fins installed on the outside of their copper tubes, which increases their heat exchange efficiency. These fins are specifically produced by a copper fin machine.

- Titanium alloy

In some special chemical industries, chlorides and chlorine have strong corrosiveness and can corrode metals in a short period of time. In order to take into account the lifespan of the Tube in tube heat exchanger, it is necessary to use titanium alloy. Its disadvantage is that it is more expensive to process compared to other metal materials.

- Hastelloy

This metal has excellent resistance to hydrochloric acid and sulfuric acid, especially in the desalination and metal refining industries. It can easily cope with high-temperature acidic use scenarios, and is very suitable for use in extreme chemical environments.

- Hydrophilic aluminum foil.

Some heat exchangers require higher heat exchange efficiency and capacity, so a large number of aluminum fins are installed on the outside of the bundle to increase the heat dissipation area. These aluminum fins have a layer of hydrophilic membrane on the outside, which will not oxidize even when used in water.

- Plastic paper

A complete heat exchanger needs a plastic wrap to seal the flange interface before packaging, to prevent dust and other items from falling into its interior, causing unnecessary trouble. The function of the plastic wrap is to seal the outlet and inlet, and its another function is to serve as a label, providing textual instructions.

The structural design of Tube in tube heat exchanger

- Shell

The shell is usually a cylinder, with flanges welded and screws installed at both ends. The length and diameter of the shell determine the heat exchange area and efficiency. These dimensions are usually designed according to the user’s requirements.

The type of fluid media determines the material of the shell, and the corresponding metal materials are used to control its manufacturing cost. There will be two interfaces on the side of the shell, which are for connecting the external inlet and outlet.

- Bundle the tubes.

This is the core component of a tube heat exchanger, where heat transfer occurs. Therefore, each different heat exchanger bundle has a distinct design, such as one with low fins on the outside, one that is spirally bent, or one with aluminum fins installed on the outside, among others.

Like the shell, it also selects different metal materials to meet the strict usage scenarios in order to satisfy the corrosion resistance and acid resistance of the fluid.

- End cap

The function of the end cap is to seal the shell and form a complete tube heat exchanger. It is using a CNC machine, and the material conforms to the shell. The two end caps on both sides are the same in shape and size, but there will be some minor differences inside.

- Flange connector

The material of the flange joint is usually the same as that of the shell and the end cover. However, as part of the factory’s machines, it has higher requirements for manufacturing precision. High-precision machine tools machine the connection contact position to avoid leakage at the connection point.

wechat

wechat