Overview

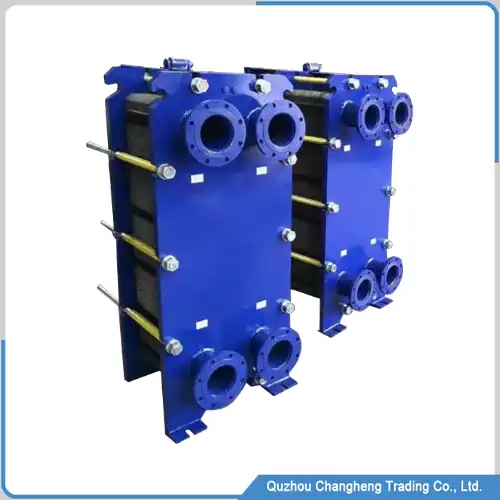

The shell and tube heat exchanger adopts a cylindrical shell with uniformly arranged tube bundles inside, assembled in a sealed manner to allow two different media to exchange heat.

This structural design helps to withstand greater pressure and eliminates concerns about pressure leakage during long-term use.

Some shell and tube heat exchangers have internal tube bundles that pass through fins. The tube bundles expand and tightly bond with the fins, increasing the heat transfer area and improving efficiency. This structure is currently one of the most effective heat transfer methods.

Advantages of shell and tube heat exchanger

The design structure of this heat exchanger is simple, and manufacturers can easily replace different configurations to meet the needs of various industries. Therefore, in modern industrial applications, its advantages are very obvious, with the following main features.

- Simple structure and cost

Thanks to its simple structure and no complex manufacturing process, its important advantage is low cost, which has a significant cost advantage compared to plate-type heat exchangers.

- Strong pressure resistance

Thanks to the strict requirements for the shell’s metal and the thickness of the connecting flange, it has the best pressure resistance of all heat exchangers.

- Easy to clean

During long-term use, it is inevitable that dirt and impurities will settle in the heat exchanger. Because the internal structure of the shell and tube heat exchanger only consists of tube bundles, its internal cleaning is very easy.

- Thermal expansion and contraction

In some special industries, the tube bundle will undergo free stretching during the heat exchange process, and the shell and tube heat exchanger has good thermal compensation capability

- Strong corrosion resistance

The tube bundle and shell are made of stainless steel and titanium alloy materials, which can effectively address the issue of corrosion resistance and provide a good service life for seawater desalination and the chemical industry

Shell and tube heat exchanger data

| No. | ITEM | DATA |

| 1 | Outer pipe material | iron stainless steel |

| 2 | Inner tube material | copper stainless steel iron |

| 3 | Pipe layout | staggered |

| 4 | Heat exchange medium | water, oil, other |

| 5 | Heat exchange type | cross flow |

| 6 | Maximum pressure | 16mpa |

| 7 | Heat exchange efficiency | customized |

| 8 | Inner tube structure | straight, rotating |

Shell and tube heat exchanger Structure and Design

Our heat exchanger structure and manufacturing strictly follow the dual standards of the European Union and China, and it complies with the mandatory safety usage requirements of the European Union and other countries.

Usually, customers need to provide data such as the maximum pressure used, the heat exchange medium, the maximum temperature, the outlet and inlet temperatures, etc.

Design engineers will use computer simulations to analyze this data and obtain effective validation before proceeding with the design to ensure that the heat exchanger meets the user’s needs.

Other heat exchangers

Industrial heat exchanger of shell and tube type

Product Description This industrial heat exchanger is of the tube and shell type and is one of the most popular devices in modern production. In many industries, it is necessary…

Shell and tube heat exchanger

Overview The shell and tube heat exchanger adopts a cylindrical shell with uniformly arranged tube bundles inside, assembled in a sealed manner to allow two different media to exchange heat….

Plate heat exchanger for selling

Product Description This plate heat exchanger type is one of the most popular, consisting of many stacked metal plates. The edges of the metal plates are sealed with EPDM gaskets,…

Shell and tube heat exchanger application

- Chemical Industry

- Food and Beverage Industry

- Energy industry

- Power industry

- Ship and Aerospace

- Refinery

- Seawater desalination

- Water supply project

Plate heat exchanger factory video

Our Support and Services

- Accepting customized shell and tube heat exchangers of any size

- Repair and refurbishment of heat exchanger products

- A leading manufacturer in China, providing high-quality services

- New heat exchanger design and technical support

Summarize

Shell and tube heat exchanger is a modern product with a simple structure, easy manufacturing, and low price advantages. It is widely used in various industries. Its internal arrangement of pipes can withstand high pressure for heat exchange. Even corrosive media have a long service life.

If you need a shell and tube heat exchanger, choose us. We can offer a good price and excellent technical support and after-sales service.

wechat

wechat