Product Introduction

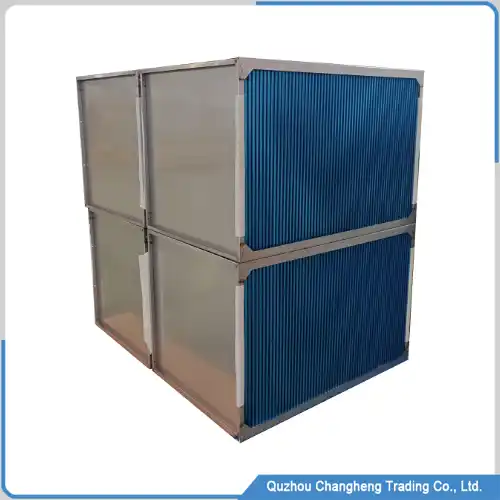

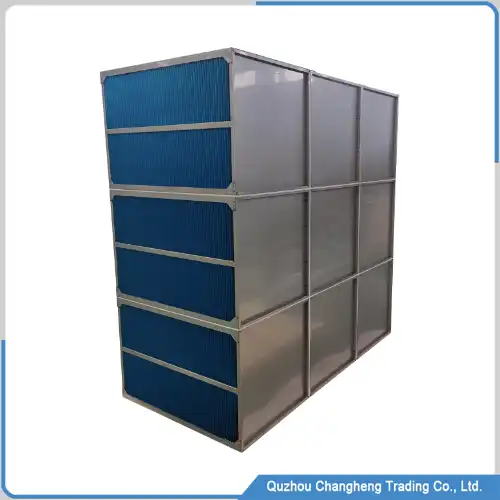

This counterflow heat exchanger is an air heat exchange product formed by pressing hydrophilic aluminum foil and then cross-stacking to form a convective channel. Cold and hot air flow cross each other for heat exchange. It is the energy exchange and recovery in civil, commercial, and industrial ventilation systems.

In some harsh environments, such as industrial areas, coastal cities, etc., the core of this countercurrent heat exchanger will use stainless steel 304 as the main material, which effectively guarantees its service life.

Its shapes include polygon, circle, rectangle, and square, with square heat exchangers being the most widely usening.

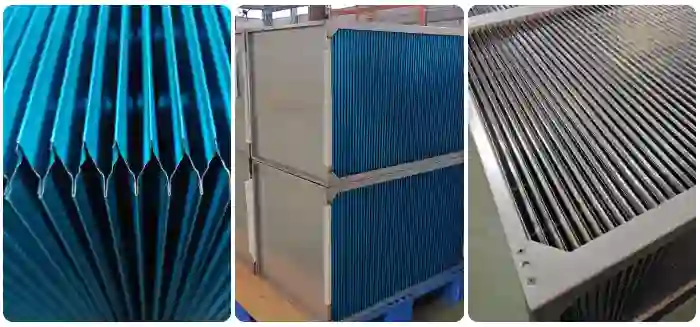

Its structure is composed of multiple aluminum plates stacked in a cross pattern, and the edges are bent twice using special tools to ensure good sealing.

Counterflow heat exchanger raw material

| No. | Part Name | Raw Material |

| 1 | Foil plate | aluminum stainless steel optional |

| 2 | Door lock | stainless steel 304 |

| 3 | Door | stainless steel 304 |

| 4 | Framework | stainless steel 201 |

| 5 | Base | Carbon steel nickel plated |

| 6 | Air outlet | flange plate |

| 7 | Air inlet | customized plastic |

| 8 | Air filter | melt blown cloth |

Counterflow heat exchanger characteristic

Raw material

Its internal material is generally hydrophilic aluminum foil or stainless steel 304, and some special heat exchangers use plastic and special paper. However, metal materials are the most widely use because metal raw materials not only have good thermal conductivity, but also have a long service life.

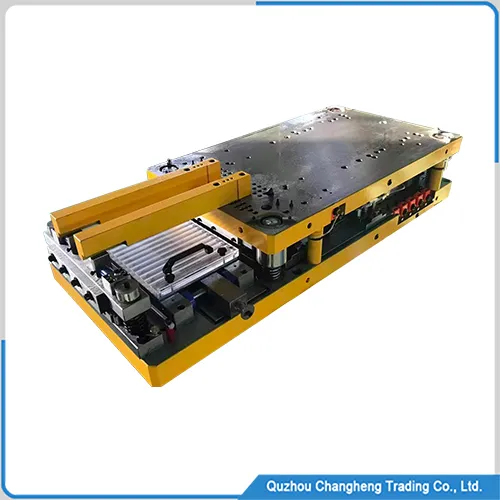

Production process

Its structure is formed by pressing metal plates and then cross stacking them. The convex hull of the two plates contacts to form a channel, and the edges of the plates are bent twice for sealing,

The top plate, bottom plate, and bracket of the heat exchanger are fixed with screws to form a complete heat exchanger core. The four corners need to be seal with glass glue to avoid cross contamination of the two types of air.

How to Work

A counterflow heat exchanger is a functional product that has two independent air channels. Fresh air from the outside enters one channel into the room, while indoor air is discharge from the other channel. They undergo energy conversion inside the heat exchanger.

This product has no power and needs to be installed in a ventilation device for use. The ventilation device has many functions, such as air volume control, air filtration, humidity control, etc., and this cross flow heat exchanger is one of the most important functions for converting thermal energy.

Quick Details Of Heat Exchanger

- Aluminum plate size range:

- 200*200mm

- 300*300mm

- 400*400mm

- 500*500mm

- 600*600mm

- 700*700mm

- 800*800mm

- 900*900mm

- 1000*1000mm

- 1100*1100mm

- 1200*1200mm

- 2000*2000mm

- External dimensions: customized according to customers

- Plate raw materials: hydrophilic aluminum foil, stainless steel, TP plastic film, etc

- Packaging: Wood frame

- Delivery time: The earliest delivery time is 25 days

- Customized size: Yes

Counterflow heat exchanger manufacturer factory video

Application scope

With people’s quality of life improving, their awareness of environmental protection is becoming stronger, so the prospects of this heat exchanger are up and coming. The following application scenarios are just some examples.

- Office Building

Usually, for the sake of building aesthetics, these buildings have hidden ventilation ducts on each floor, and these channels are have with this counterflow heat exchanger,

Those office buildings equipped with central air conditioning will install this type of heat exchanger to save energy consumption

- Computer data center

Long term operation of computers generates a large amount of heat, and in order to avoid wasting this heat, this heat exchanger effectively recovers this heat, which can save a lot of energy.

- Indoor Agriculture

Indoor plant growth requires a suitable temperature, which may be too high during the day and very low at night. Therefore, a ventilation device is needs to effectively control the appropriate temperature.

- Industrial Thermal Management

In some thermal management factories in the industrial field, to avoid energy waste, An air system is need to prevent the waste of heat energy.

Support and Services

Our heat exchanger has two different working modes, hot and cold air exchange and cold and hot air exchange, and fully considers the temperature and humidity of the air, which will not affect its service life.

We can produce any heat exchanger; whether you want to buy large-sized products such as 1200 * 1200mm for industrial use or small-sized products for home and office use, we can meet your diverse needs.

The aluminum foil of this cross-flow heat exchanger is made of 0.12mm thickness, which not only has good thermal conductivity but also has a long service life. We guarantee that there will be any quality problems within 12 months, and we provide free replacement service.

wechat

wechat