Machine summarize

The Radiator fin rolling machine is an efficient production equipment suitable for producing louvers for radiator fins. This equipment uses two roller molds and produces heat sink fins through a rolling process, with high production efficiency and stable quality.

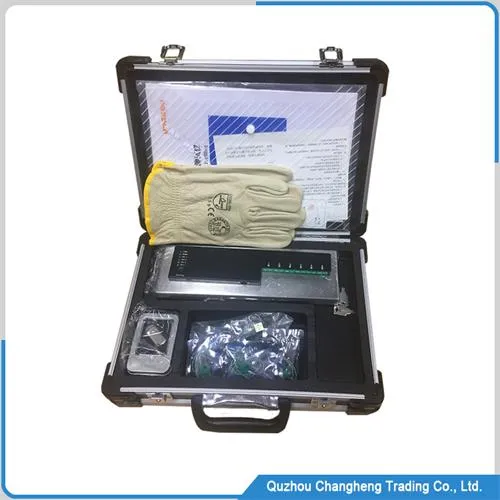

The equipment’s components include an aluminum foil uncoiler, an aluminum foil stable transmission device, two rolling dies, a counting control tool, a cutting tool, and a control system.

The aluminum foil uncoiler rolls the aluminum foil into a cylindrical shape, and through a stable transmission device, it is transported to a rolling die for rolling. After rolling, it is counted using a counting control tool and then cut using a cutting tool to obtain the required radiator fins.

Fin rolling machine peculiarity

The radiator and heat sink rolling machine speed is very fast, reaching 120 meters per minute, and the production efficiency is very high.

Large OEM factories typically use this equipment to produce heat sinks and fins, as they can customize any roll mold size to meet different market demands. The minimum dimensional tolerance can be within +/-0.02 mm, ensuring the quality and accuracy of the radiator fins.

The fin-rolling machine adopts a PLC control system, and the human-machine interaction adopts a touch screen, which can achieve high automation and high-precision control.

The electrical components come from internationally renowned brands such as Siemens and Mitsubishi, ensuring the equipment’s stability and reliability.

The radiator and heat sink rolling machine is suitable for various occasions that require efficient heat dissipation, such as aviation, ships, automobiles, machinery, and other fields.

Technical data

| NO. | ITEM | DATA |

| 1 | motor power | 2.2kw |

| 2 | Pitch | 2 to 4 mm |

| 3 | Fin type | louvre straightness |

| 4 | fin Width | 12-102 mm combination |

| 5 | max speed | 0-120M/min (CVT) |

| 6 | Max cut-off | 60 times/min |

| 7 | Air pressure | 0.4- 0.6 MPa |

| 8 | Fin Height | 3.5-12 mm combination |

| 9 | Delivery time | 45 days |

| 10 | Machine weight | 1500kg |

Field of use of this fin-rolling machine

This condenser fin machine mainly produces foil made of aluminum and copper materials with a thickness of about 0.05-0.12mm. Its fins can be useing in car radiators, AC condensers, air conditioning heaters, car evaporators, oil coolers, etc.

If you want more details about this machine, don’t hesitate to contact our engineer. We will send you all the information about this fin-rolling machine.

Q & A

A: The touch screen is 7 inches, and we can customize larger sizes.

A: The width size of our fin roller can be 6-200mm.

A: Of course, we can manufacture fin roller without blinds.

wechat

wechat