Product Description

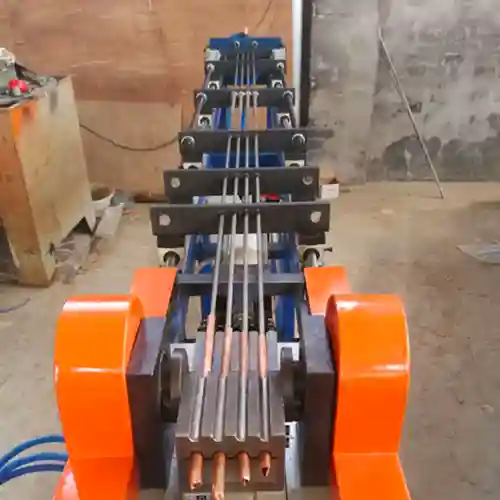

This is a tube bend machine that can bend four tubes simultaneously, with a maximum bending tube length of 2,800 mm. It is also compatible with other sizes, and the minimum length can be 150mm. We can customize the bending angle and center distance of this machine to match the size of the user’s heat exchanger, ensuring it meets the user’s production needs.

The tool for bending tubes features an independent design, allowing users to replace different tools as needed for production. This enables the bending of tubes with various diameters and angles, meeting diversified production requirements.

This tube bending machine uses the latest technology, is driven by a 2.2 kW servo motor, and features a 1:10 reduction ratio. Two parts work together precisely to produce mighty power. Whether it’s bending copper, aluminum, or stainless steel materials, it can easily process these metal tubes.

These metal tubes are widely used in modern products, such as air conditioner condensers and evaporators, in both household and industrial applications.

Tube bend machine parts brand

| PARTS | BRAND |

| Electric control system | Mitsubishi and Omron |

| Pneumatic components | SMC, ADK |

| Hydraulic system | Using oil grinding |

| Electrical components | Omron, Mitsubishi |

| Touch Screen | DELTA |

| Electric motor | DELTA |

| Bending tool | Self-created |

| Thimble | Self-created |

Advantages of the tube bend machine

The brand-new design enhances efficiency

Compared to the old hydraulic-driven machines, it not only dramatically improves production efficiency but also allows us to freely control the bending angle, which is crucial for producing hairpin tubes. It can keep the tubes on both sides perfectly parallel.

Dual servo motor drive

The machine differs from the hydraulic station, and both the bending tube and the material return utilize servo motors as their power source. It not only produces powerful output, but also generates less noise than 68 decibels during the production process.

Intelligent control

We use PLC and touch screens for the intelligent control of equipment. Production parameters are interacted with by humans and machines through touch screens, which are equipped with various production modes. Workers can select different production modes based on the size and shape of the tube to enhance work efficiency and product quality.

Compatible with multiple sizes.

The positioning device of the tube features a flexible design, eliminating the need for mold and tool replacements, and is compatible with various sizes, thereby effectively reducing the machine’s operating costs.

Tube bender machine working video

Other heat exchanger machines

Tube bending machine for Heat exchanger hairpin tubes

Machine Overview A tube bending machine, also known as a pipe bender, elbow machine, or tube bender, is a piece of equipment designed to bend metal tubes into precise shapes and angles. The primary function of this device is to…

Bender pipe machine of hydraulic Semi-automatic

Machine Outline The bender pipe machine is a device specifically designed to bend straight pipes into U-shaped tubes, and it is widely used in the heat exchange industry. The device adopts a semi-automatic production method, where workers insert pipes into…

Fin production line of Heat exchanger | fin punching line

Production line overview The High-speed Heat exchanger fin production line is a special cast iron alloy with high rigidity and shock resistance. The slider is designed with a long guide circuit and equipped with a slider balance device to ensure…

The advanced features of the tube bend machine

- Foot switch control.

This bending machine features not only a manual button switch to control its operation, but also a foot switch, which helps improve work efficiency. Workers can choose to control the machine using their feet or hands.

- Baking paint process

Due to China’s increasingly stringent environmental protection requirements, the paint of this machine must be sprayed in a professional factory. After spraying, it is baked at a high temperature. The appearance of this paint process is exquisite, close to the surface of a car. It not only has a beautiful appearance, but also resists rust and fading.

- Multilingual touchscreen page.

We assume that the touchscreen of the tube bending machine is set in two languages, Chinese and English. If you are from Russia or countries such as Brazil and Argentina, we can offer additional languages for the touchscreen of this machine, including Russian, Portuguese, Spanish, and others.

After-sales policy

- The warranty period for this hairpin pipe bending machine is 12 months, which is in line with China’s laws and regulations. During this period, we will provide free maintenance services if the machine encounters any malfunctions.

- If the machine is damaged due to human factors, we will also provide repair services; however, the buyer is responsible for covering the costs of our engineers’ airfare, hotel, and visa expenses, among others.

- As for the delivery time of the pipe bending machine, we will provide sufficient machine parts. Generally, this machine can be useing in the user’s factory for 3-5 years without any problem.

- In the future, if any parts of the machine wear out and cause a malfunction, we can provide spare parts, and you only need to pay the air express fee.

- We offer technical support for the production of heat exchangers and condensers, and provide free training for your engineers. However, you need to cover the travel expenses of our engineers.

wechat

wechat