Application of furnace temperature tracker

As a new product in the field of furnace temperature detection, the furnace temperature tracker has brought us great convenience. In the future,

industrial production urgently needs to popularize temperature-measuring devices in furnaces. A furnace temperature tracker is a temperature-measuring instrument related to heating equipment,

which has been widely used in many industries. This usually refers to the detection instrument that can measure the heating temperature of the product. The system can work usually in high-temperature environments with high precision.

Do you know the convenience of a furnace temperature tracker? Furnace temperature tracking technology promotes the rapid development of the market economy.

The quality of the furnace temperature tracker shall be guaranteed when purchasing, especially the products of the furnace temperature tracker that shall be selected.

Only the furnace temperature tracker with good quality can be selected, which is beneficial to us, so I hope you should choose it carefully here.

Its advantage is that the measurement process is very simple and the use method is also straightforward. All collected data will be actively stored in the database, so you only need to enter data when using it.

Second, to prevent language communication obstacles, the furnace temperature tracking system is configured with multiple languages to facilitate our operation.

There are simplified Chinese and traditional Chinese for easy operation.

Its working environment must be at a high temperature, so its configuration should be high temperature resistant to prevent high temperature.

When the internal temperature is too high, the machine stops running, and turns the temperature detection function off.

When the internal temperature of the instrument exceeds 70℃, the switch will close. Its operation requirements shall not be too high.

It is still available under 1.8vdc voltage control and is entirely unaffected. For a high-quality furnace temperature tracker,

the operating system is very fixed. Only in this way can the data be tested and analyzed effectively. To judge whether a machine is good or bad, we should look at its running speed.

Of course, the efficiency is very high

Special functions of furnace temperature tester

What are the special functions of the furnace temperature tester? Although he said that he can measure the temperature, and the degree of high-temperature resistance varies,

Perhaps when we mention the furnace temperature tester, we all think that maybe the furnace temperature tester is like our thermometer,

which is a thermometer used in industrial production, but it is not.

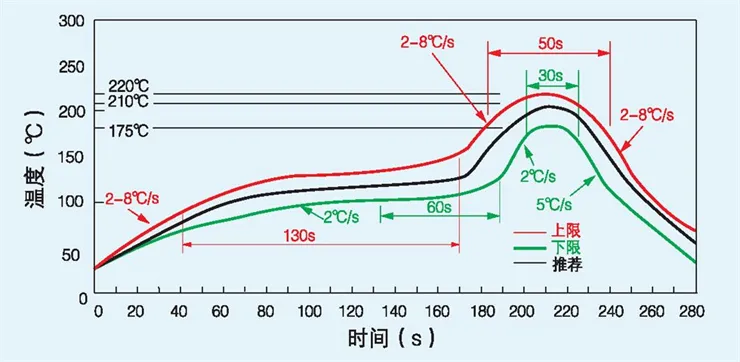

Using the furnace temperature curve tester, the temperature curve test is straightforward, and any operator can quickly obtain the best process. The electronic data analysis software e-data pro can accurately reflect the perfection of the temperature curve,

Guide the operator in completing the debugging process of the equipment temperature curve, making it accurately meet the process requirements, minimizing the wrong temperature setting, and avoiding various defects affecting the product quality.

Tc-60kii furnace temperature curve tester function: it can cope with the most severe lead-free process and withstand harsh industrial environments; it has High efficiency,

can continuously store 256 groups of data and can choose to download to the computer for grouping analysis and processing;

Ensure that the products meet the welding specifications and reduce defective products or rework; It can highlight the cold and hot spots in the furnace.

Find out the problems in the furnace, use the temperature curve data to find out the causes, and put forward improvement suggestions

so as to save the time and money required for furnace temperature setting. Furnace temperature tester can maximize production efficiency and reduce energy consumption;

Maximize production capacity. Facilitate efficient and accurate verification of new products. The product is accurate, reliable, small in size, and large in storage capacity (80000 data points/channels).

It is stored by flash chip without losing data in case of power failure;

The furnace temperature tester can accurately measure the temperature in the industrial processing furnace and ensure no error in the production and processing process.

Only by mastering the product production temperature can the product quality be improved

wechat

wechat