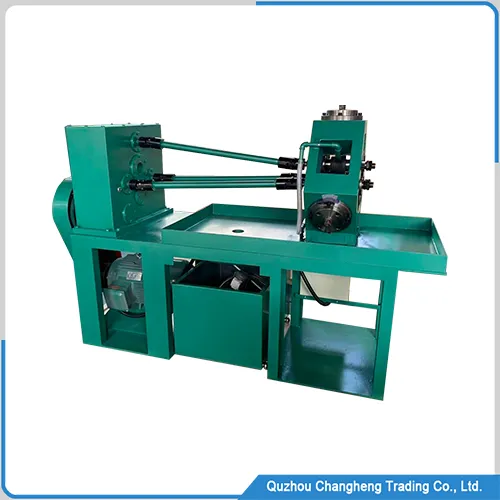

extruded fin tube machine outline

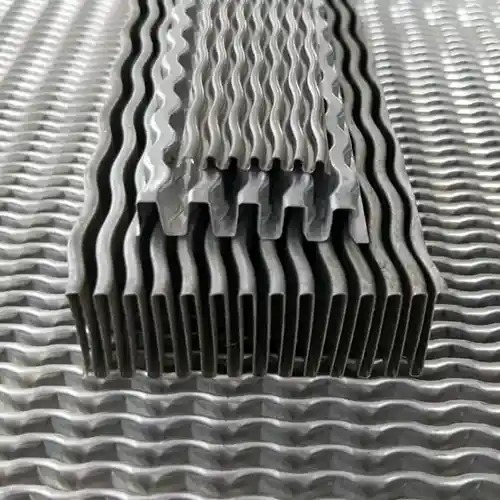

This extruded fin tube machine nests two types of metal tubes together and compresses the outer tubes to form threaded fins, The inner tube can be made of any metal material, and the outer tube is usually made of aluminum or copper material

The tube fins are formed by machine extrusion, and the fin base and the outer wall of the tube closely fit. This type of fin tube has an excellent heat conduction function

Fin tubes are key components of air coolers, and large-scale heat exchangers and steam condensers are also widely used, so the application of extruded fin tube machines is very extensive

Compared to other types of fin tubes, extruded fins are stronger and more resistant to corrosion. Finned tubes can be cleaned more easily when used in steam or high-pressure

extruded fin tube machine data

| No. | ITEM | DATA |

| 1 | Outer Fin height | <17mm |

| 2 | Outer Fin material thickness | 0.2-0.6mm |

| 3 | Outer Fin material | Aluminum, Copper optional |

| 4 | Base tube diameter | 10-38mm, 8-51mm |

| 5 | Fin tube outer diameter | Φ25-88mm |

| 6 | Fin pitch | 0.6-2mm 1.6-5mm |

| 7 | Max length | <20m |

| 8 | MOQ | 1 pcs |

| 9 | Delivery time | 65 days |

| 10 | Base tube material | Aluminum, SS304 copper, alloy |

Advantages of Fin Tube Machines

1, Adopting a design of three-axis rollers makes the force more uniform and improves the efficiency of the equipment.

2, The control system is simple, and workers can directly operate without receiving training, reducing the threshold for use.

3, The extruded fin tube machine is equipped with an automatic circulating cooling system, which can effectively prevent the roller mold from overheating and extend its service life.

4, The length of pipes produced by the equipment is not limited, with a maximum length of 20 meters, meeting the needs of large-scale production.

5, The roller mold is designed to be replaceable, allowing for the production of different sizes of fin tubes by simply replacing the mold, reducing production costs.

Our success stories

extruded fin tube machine working video

Q & A

A: The appearance color of our machine can be customized, and the default color is green.

A: If you purchase our machine, we provide free installation services, but you need to pay for the engineer’s air tickets, hotel, and food.

A: The delivery time for this machine is 41 days.

A: Yes, the fin rollers of this machine can be replaced, However, we do not recommend this because the rollers are assembled with multiple blades, and frequent replacement can reduce the tightness.

wechat

wechat