Machine Overview

The fin machine is an industrial production equipment. In different industries, the production methods and solutions of the fin machine are different. Some machines use roller extrusion, while others use highly stamped production. It plays a crucial role in many industries, especially in the cooling industry and heat exchange industry. It is inseparable from the fin machine to participate in production.

This article mainly introduces several popular fin machines required for the production of different types of heat exchangers, as well as their production methods and working characteristics.

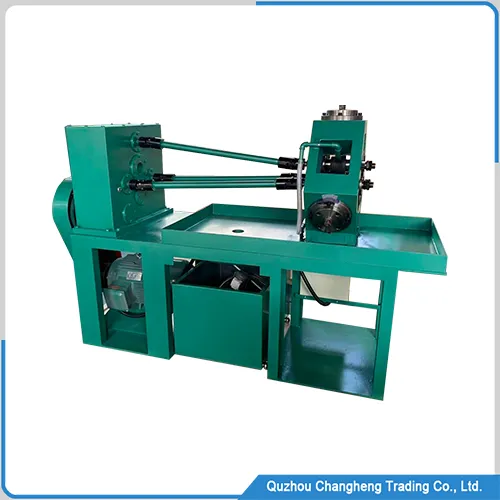

Aluminium fin press machine

This is a continuously produced aluminum fin machine that uses a 7.5kW motor to drive the spindle to rotate, uses a cam to achieve stroke movement, and presses the aluminum foil into shape.

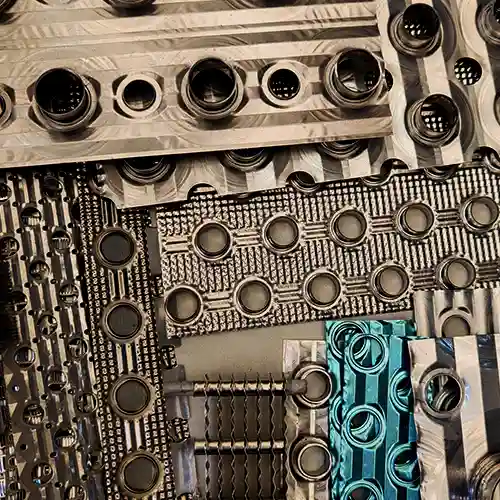

The fin mold of this machine is independently designing, allowing users to replace the mold at a very low cost, enabling the production of fins of different shapes and sizes to meet the individual needs of customers.

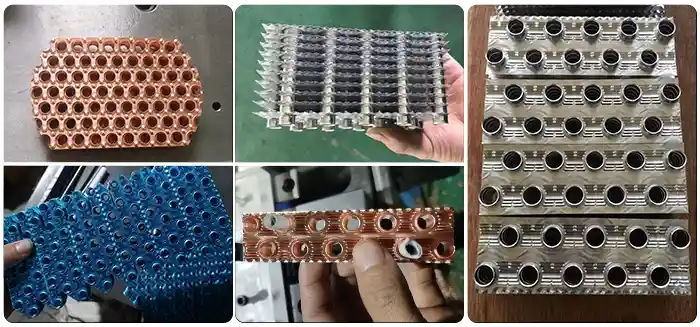

The machine is compatible with a variety of metal materials, such as aluminum, stainless steel, titanium alloy, copper, iron and other materials, so its application scenarios are very many, such as plate and bar heat exchangers, engine coolers, washing machine dryers, battery panel cooling, etc.

Fin press machine features

Wide range of application scenarios: This machine is the most widely useing of all fin machines, and it involves industrial cooling, thermal power plants, trains, battery cars, microelectronics, etc

Unique structural design: It uses multiple sets of cams to achieve left-right and up-and-down movements, achieving high-speed production of 140 times per minute

Multilingual adaptation: The touch screen has built-in multiple languages, Chinese, English, Russian, Korean, etc., and we accept the built-in languages you need

Long service life: It is designing with a four-column stable structure, which not only guarantees accurate dimensional output, but also guarantees a long service life

HVAC fin machine

This is a high-speed production press; its fastest production speed is 250 times per minute. The installation of fin Progressive die and suction device to achieve fully automatic unattended production, it is very suitable for large-scale production in modern factories.

This machine is available in Type C and Type H, both of which have electric regulation and overload protection functions, and are PLC-controlled and touch-screen interactive.

This production line is composed of multiple independent parts, such as a material uncoiler, a material automatic lubrication device, a high-speed stamping machine, a suction material collection device, etc.

HVAC fin machine features

Powerful power output: This press has an output power of 45 tons, and it can smoothly produce aluminum foil with a thickness of 0.6mm or stainless steel foil with a thickness of 0.3mm.

Precise electric adjustment: In high-precision fin production, accurate adjustment is very important, so the machine uses electric adjustment sliders and has a digital display.

Multi-machine highly integrated: highly centralized control of suction devices, feeding devices, blowing devices, etc., to achieve intelligent production

Intelligent alarm system: The machine has a variety of sensors. If there is any illegal operation, the touchscreen will display a fault code to prevent machine damage.

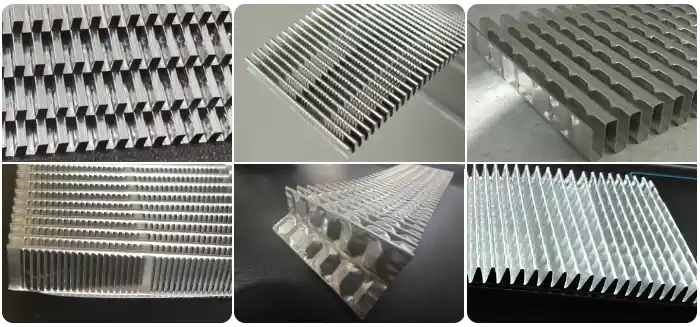

Roller fin machine

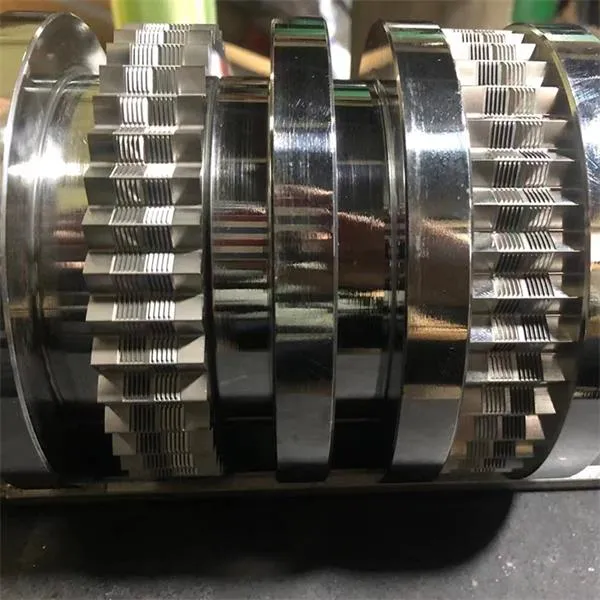

This is a special machine for the production of automotive radiators, which uses two rollers to precisely roll, cut aluminum foil into the shape of blinds, and then shape the required size.

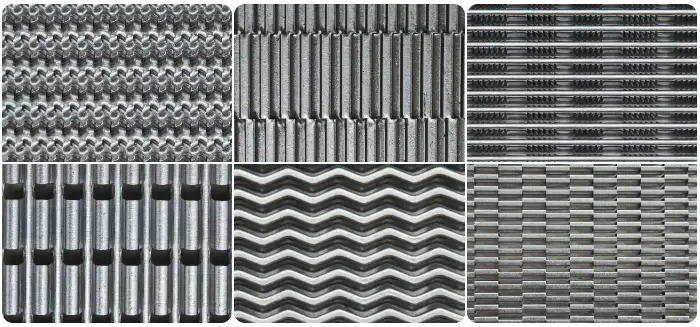

The roller mold of this machine is a complete part, allowing users to change the mold to produce aluminum fins of different sizes and shapes, such as flat type, dimple type, shutter type, etc.

In the automotive engine cooling industry, this is the most critical equipment, such as automotive air conditioner heaters, air conditioner condensers, turbocharged intercoolers and other parts; they all need this machine to participate in production.

Roller fin machine features

Built-in lubrication device: an automatic lubrication system, which can automatically supply its lubricating oil according to the production speed.

Precise cutting: Servo motor controls the length and size of the fin to ensure that each fin maintains a high degree of consistency.

High-speed production: This machine can roll 120 meters of raw material aluminum foil per minute, which is at the forefront of current industrial manufacturing.

Multi-size application: The roller mold adopts a multi-size design, which means that a mold can produce a variety of radiator aluminum fins of different widths, such as 16mm, 26mm, 36mm, 48mm, etc.

Other more industrial fin machines

Our range of machine services

- Size customization service

We manufacture the size and shape of the fin mold according to the user’s requirements. No matter what kind of machine you are, we can provide the best solution and the most competitive price.

- Technical training services

The functions and control methods of the new fin machine will be different, which may be challenging for your engineers. Our technical team will solve this problem for you. They will not only train your engineers on the regular use of the machine, but also teach them to maintain these machines.

- Long-term parts supply

These machines are high-precision production equipment, and some parts are specially manufacture and vacuum hardened. They cannot be purchased smoothly through the aftermarket. We provide a long-term supply of such vulnerable parts.

- Excellent after-sales support

Our technical team has an average of more than 10 years of experience. For some minor problems encountered by the fin machine during the production process, our engineers can solve 90% of the fault problems online. If it is necessary to have our engineers arrive at your factory, we will also respond quickly.

Q & A

A: These machines can produce many types of metal fins, such as copper, aluminum, stainless steel, titanium alloys, etc.

A: We have this machine; you can contact our engineers to get complete details of this machine.

A: The delivery time for this machine and fin mold is 65 days, and the delivery time for other machines is 45 days.

A: We can provide you with complete production and technical training services, a one-stop solution to all your problems.

wechat

wechat