vacuum aluminum brazing outline

Vacuum aluminum brazing service is an advanced metal aluminum welding technology that can be widely used in aerospace, automotive manufacturing, electronics, power, and other fields.

As a leading provider of this technology, we are committed to providing engineers with the highest quality service and the most advanced technology.

Our service team is composed of engineers and technical experts who have worked in this field for over 15 years and can provide you with high-quality and efficient vacuum aluminum brazing services.

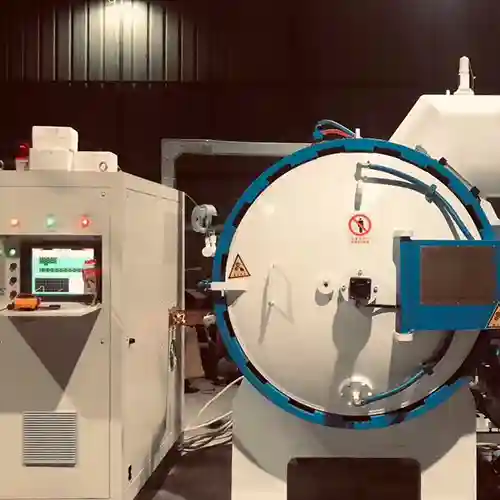

We use the most advanced vacuum brazing equipment to ensure that each riveting point meets extremely high-quality standards,

thereby ensuring that your heat exchanger, oil cooler, and aluminum products have good performance and reliability.

| ITEM | DATA |

| Product name | vacuum furnace |

| Service Item | Brazing Technology |

| Raw material | aluminum |

| Service area | worldwide |

| Length of time | No limit |

Our Strengths

High reliability: Our service adopts the most advanced technology,

without adding any soldering flux, with a full and glossy weld, and accurate product size without deformation

Low environmental pollution: Aluminum brazing is conducted in a vacuum environment, avoiding environmental pollution and material loss.

Efficiency: Our service team has rich experience and professional knowledge,

which can quickly and accurately solve various problems and improve production efficiency.

Customized solutions: We can provide customized solutions based on customer needs and requirements to meet customer needs.

Equipment supply: We can also supply all machines from A-Z, such as vacuum furnaces, aluminum fin machines, core assembly machines

summary

Our vacuum aluminum brazing service is far more than that. We will train your engineers to master this technology in the shortest possible time, saving you time and cost; Gain more advantages in market competition

If you are looking for an efficient, reliable, and beautiful aluminum brazing solution, please try our aluminum brazing service.

Our team of engineers can provide professional advice and solutions based on your needs to ensure the successful completion of your project. Contact us quickly to enjoy this new welding experience

wechat

wechat