Product Description

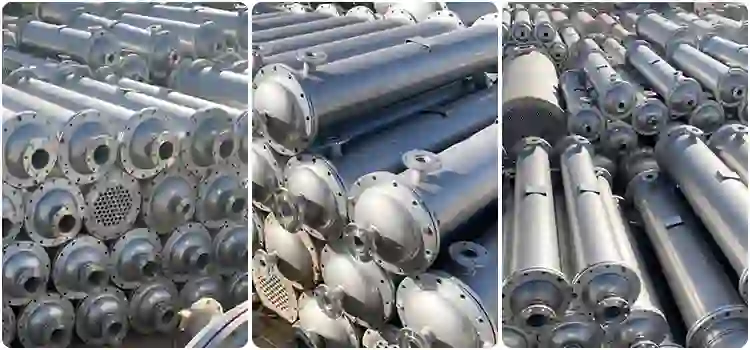

This industrial heat exchanger is a tube-and-shell structure, where two fluid media exchange heat. It is one of the most popular equipment in modern industrial production. Its unique high-pressure resistance and super long service life make it widely used in the petroleum refining and chemical engineering industries.

There are a lot of tubes inside the heat exchanger, which are scientifically arranged and evenly distributed to ensure that each tube can fully contact the fluid. The material of these tubes is usually carbon steel, stainless steel, titanium alloy, etc. Different metals are useing for other media to meet corrosion resistance needs.

These tubes are connected to the end plates, and the end plates and tubes are fully contacted using the tube expansion process. Then they are welded together using the argon arc welding process. This process can effectively ensure the heat exchanger guarantees a longer service life in harsh environments.

Advantages of industrial heat exchangers

Strong corrosion resistance.

Its internal U-shape tube is made of SS304 and titanium alloy, preventing it from being corroded after long-term use. It can guarantee a long lifespan even if used in highly corrosive environments such as seawater desalination and the sulfur industry.

The ability to withstand high pressure.

Due to its unique internal structural design and the use of tube expansion and argon arc welding techniques, it can withstand a maximum operating pressure of 30 MPa. This pressure resistance can meet almost all application scenarios in modern industry.

Flexible temperature control.

Using a heat exchanger is crucial to control temperature changes effectively. Adjusting the temperature of this heat exchanger does not require a complex operation process. Engineers only need to rotate the valve, and they can easily control its temperature by controlling the speed of the fluid.

It won’t consume electricity.

In the process of heat exchange, it won’t consume electricity or other usage costs, which means you only need to invest once and use it for a lifetime at zero cost.

Industrial heat exchanger data

| ITEM | DATA |

| Pipe material | SS304 titanium |

| Maximum pressure | 30Mpa |

| Tube type | U type |

| Cooling method | cross flow convection |

| Size | Customized |

| Packaging | wooden box |

| MOQ | 1 pcs |

Material: stainless steel/carbon steel, optional

Heat exchanger area: according to working conditions

Working/Design temperature: according to the design, optional

Pressure: according to the design, optional

Application: oil, chemical, pharmacy, food, electricity, paper…

Manufacturing process of Industrial heat exchanger

Part characteristics

End plate: The features of this plate, such as steps, grooves, chamfers, threaded holes, and straight holes, are all manufactured by CNC machining tools. This ensures that the spacing error of each hole is control within the range of 0.1mm.

Tube: Its material is usually stainless steel, iron, copper, titanium alloy, etc. (Different fluid media require different materials). It is bent into a U shape using special industrial tools and then installed on the end plate.

Fin: This special fin is produced by high-speed punching machines, and its function is to increase the heat transfer area and improve the heat exchange efficiency. Some high-efficiency heat exchangers do not need to install with these fins.

Shell: A cylindrical metal shell selects the appropriate wall thickness depending on the usage scenario and pressure requirements. It is formed into a desired shape through drilling and welding flanges, and then undergoes polishing and surface treatment.

End cap: The production process of this evaluation is the same as that of the shell parts. The hole size of the end cap flange and shell flange must be the same, because they need to be connect.

Installation: Installing the tube must follow the design plan, as it requires a scientific distribution. Otherwise, it will make the two media cross-mix. Therefore, installing the tube is an important job that skilled engineers must do.

Production process

Welding: Welding is needs after connecting the tube and the end plate. The welding process directly determines the sealing and service life of the heat exchanger. Our heat exchanger uses a professional argon arc welding machine to automatically weld these tubes, guaranteeing the welding quality and improving production efficiency.

Assembly: After all the parts are ready, the heat exchanger must be assembled. Some parts must be manually polished during this process to ensure their sealing.

Testing: Every industrially manufactured heat exchanger needs to undergo a high-pressure sealing performance test to ensure that it will not have any slight leaks under a pressure of 30MPa for 1 hour.

Packaging: After completing the heat exchanger test, it must be dried. The shell should be covered with a dust cover and a safety use label, and then it can be packed and delivered to the customer. At this point, the entire manufacturing process is finished.

Why choose our heat exchanger?

- Intelligent manufacturing.

Key parts are manufactured automatically and in one stop by CNC machines, and welding is done by automatic machines. The production process is highly quality control.

- Support for quality certificates.

This industrial heat exchanger is design for ultra-high pressure and is a special pressure vessel. It requires a mandatory pressure use certificate in developed countries such as Europe and America. We can provide these certificates for you to smoothly clear customs and use them as usual.

- Customized services.

You need to provide the technical parameters or design, and we can manufacture any heat exchanger according to your requirements to meet your production needs.

- The advantage of fast delivery.

We have been producing heat exchangers for about 20 years, and every part is making in our factory. We control the production rhythm and ensure timely delivery according to the production plan.

The final conclusion.

As an essential production tool, the industrial heat exchanger is one of the indispensable equipment in the modern industrial field. The heat exchanger produced by CHANGHENG, with its automated production and cost control, has a high competitiveness in this industry. Whether it is its independent design capability or intelligent production capability, it all meets the highest level in the industry.

Therefore, CHANGHENG might be one of your best choices if you are looking for this heat exchanger. You can click the button below to get more details and technical support.

wechat

wechat