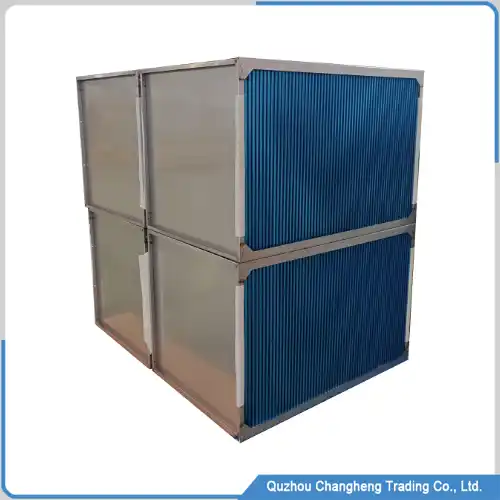

Product Overview

This shell and tube heat exchanger is a structurally simple industrial equipment composed of components such as a shell, tube plate, tube bundle, baffle, etc.

Its main features are that it can withstand high pressure, has a long service life, is easy to clean internally, is easy to install, and does not require maintenance

Due to the welding process used for the internal tubes of the shell and tube heat exchanger, It can transfer heat through various media. There is no need to worry about multiple liquid streams

Tube heat exchanger data

| No. | ITEM | DATA |

| 1 | Shell material | stainless steel |

| 2 | Tube material | stainless steel |

| 3 | Application | Chemical Industry |

| 4 | Interface | Follow Design |

| 5 | Cooling efficiency | customized |

| 6 | Heat exchange medium | oil or water |

| 7 | Process | Welding |

Tube heat exchanger Manufacturing Process

- Design

Design according to the actual needs of the customer, such as flange size, temperature, liquid medium, heat transfer efficiency, etc

- Manufacturing shell

Cut the raw material of the shell to the required length and polish it to remove any excess impurities on the surface

- Manufacturing bundling

Insert the small tube into the fin, connect it to the desired shape weld it, and then insert it into the shell. The arrangement of the tube bundle and the number of fins will affect the heat transfer efficiency

- Assembly

Assemble and weld the shell, tube bundle, and plate components to form a complete shell and tube heat exchanger.

- Testing

Leakage testing of heat exchangers is an important step to ensure their performance meets design requirements.

Characteristics of heat exchanger

- Resistant to high pressure and high temperature

The structure of this heat exchanger is very sturdy, and the thickness of the shell is very thick so that it can withstand a lot of pressure and temperature

- Use any medium

The internal Tube material is stainless steel, and the shell and tube heat exchanger can cool any liquid medium; whether it is for seawater desalination, oil refining, or the chemical industry, it can easily handle them

- Long service life

Because it adopts a welding manufacturing process, the overall structure is sturdy and firm and does not require special maintenance for long-term use

What are our advantages?

- Manufacturers from China have a significant price advantage

- We accept customization and manufacturing of shell and tube heat exchangers of any size

- Experienced engineers and workers

- The factory has been dedicated to the heat exchanger industry for many years

- Powerful industrial support provides a guarantee for fast delivery

wechat

wechat