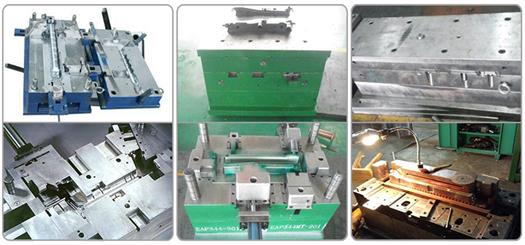

Mold Overview

The plastic injection mold is one of the critical tools for modern industrial mass production. Injection machines melt plastics at high temperatures and then inject them into the cavity of the mould at high pressure. After rapid cooling, the finished product forms. The automotive, electronics, medical and packaging industries all rely on this mold.

A set of high-quality plastic molds can run millions of times continuously. Molding system, gating system, temperature control system, and ejection mechanism make up the composition structure of plastic injection molds. Precision guidance and wear-resistant materials together determine the life of plastic molds.

Therefore, a high-quality injection mold must meet these conditions, including scientific structural design, high-quality metal materials, high-precision machining, and advanced engineers’ modular assembly

Plastic Injection mold material

- Chamber: P20

- Top pin: NAK80

- Sliding block: Cr12MoV

- Spring: 50CrVA

- Base plate: EN C45,

- Injection port: 4Cr13MoV

- Mold frame: EN C45

Table of contents

Plastic Injection mold data

| ITEM | DATA |

| Place of Origin | Zhejiang, China |

| Brand Name | CHANGHENG |

| Product Material | PA66-GF30 |

| Mold color | Any color |

| Cavity | 1-4 unit |

| Surface treatment | Mirror Polish |

| Application | Car radiator |

Manufacturing process of a Plastic injection mold

Design programming phase

Engineers first use the design software UG or SolidWorks to establish a three-dimensional model of the mold. Moldflow analysis predicts that the melt can flow smoothly, avoiding defects such as short shots and welding lines. CAM automatically generates CNC machining programs and locks tolerances within ± 0.01 mm. The electrode paths of the plastic injection mold are optimized synchronously to reduce the machining empty travel.

Precision machining stage

Slow wire cutting ensures that the verticality of the plastic injection mold insert is less than or equal to 0.005mm. Copper electrode EDM etching texture, surface roughness Ra ≤ 0.4µm. Five-axis high-speed milling completes the curved surface of the plastic mould, and the chamfer radius can be as small as 0.1mm. The cooling water channel hole diameter tolerance is H7, which is conducive to uniform heat dissipation of the plastic injection mold.

Assembly and commissioning stage

The gap between the guide post and the guide sleeve is controlled within 0.02mm, and the plastic injection mould opens and closes smoothly.

After the first mold trial, the flash can be eliminated by fine-tuning the gate size by 0.05mm.

The ejection balance test ensures that the plastic injection mold is released simultaneously in the case of multiple cavities.

Plastic injection mold design requirements

- The demoulding slope is usually ≥ 1 ° to ensure that the slider and core of the mold can be safely withdrawn.

- Multi-cavity layout of plastic moulds can improve production efficiency, but it is necessary to ensure that each part is demoulded and unloaded simultaneously.

- The thimble plate must have a quenching gasket to ensure that the working life of the plastic injection mold is extende.

- Cooling water from the cavity, 12 – 15 mm, the injection plastic mould temperature layer is minimize.

- After finite element analysis of the key stressed components, the yield strength is greater than or equal to 1,500 MPa, ensuring the safety and reliability of the mold.

Plastic injection mold materials and characteristics

Die steel material selection

P20 pre-hardened steel hardness HRC30 -36, suitable for plastic injection molds for home appliance shells.

NAK80 mirror grade hardened steel, hardness HRC40-45; this material is the first choice for the production of transparent plastic parts.

S136 corrosion resistant stainless steel hardness HRC48 -52, PC high temperature material plastic injection mold must be selected.

surface strengthening

The depth of the nitride layer is 0.1 mm, and the wear resistance of the sliding surface of the plastic injection mould has increase threefold.

TD coating hardness HV2 800, plastic mould thimble life extended by five times.

The chrome plating layer is 0.003 to 0.005 mm, and the surface of the plastic mold is not sticky, resulting in a 20% reduction in demoulding resistance.

Plastic injection mold production cycle and delivery

The standard mold lead time is 25-45 days. Large automotive parts molds require T0-T3 four mold trials, and the production cycle is usually 60 days.

We guarantee the shortest delivery time for injection molds with a standard mold base design of 15 days.

Medical-grade plastic injection molds must be ISO 13485, and the production cycle needs to be more by 5-7 days.

What are our advantages?

- We focus on automotive radiators, and our reliable quality wins the trust of our customers.

- Our engineers have extensive work experience; regardless of the complexity of your radiator tank, we can provide high-quality molds.

- Our costs are very competitive due to our focus on large-scale production of plastic molds for automotive radiators.

- Plastic mold factories are located in cities with developed industries. If you urgently need molds, we are confident we can deliver them quickly.

Q & A

A: Our mold delivery time is usually 45 working days; in exceptional cases, it may be 55.

A: Usually, our plastic Injection molds are packing in wooden cases.

A: Our engineers can use CAD, Solidworks, Catia, Inventor, Pro/ENGINEER, ug

A: The service life of our mold is 300000 times

wechat

wechat