Product Introduction

As is well known, the production of condensers requires multiple machines. Each device completes its production task, forming a complete condenser production line. Each condenser factory has different production volumes and condenser structures, and the tools used for these devices may vary.

This article mainly introduces the machines used in the condenser production line. What are their characteristics?

What is a condenser

The condenser is a critical component in refrigeration systems, and its manufacturing process varies in different applications. For example, automotive condensers use microchannel aluminum tubes for brazing, while household air conditioning condensers use copper tubes for expansion,

The primary function of a condenser is to release the heat generated during the refrigeration process into the external environment, allowing the compressor to output low temperatures continuously,

It plays a crucial role in automotive and home air conditioning and industrial refrigeration equipment and is a key component in ensuring the normal operation of the refrigeration cycle.

Condenser production line equipment list

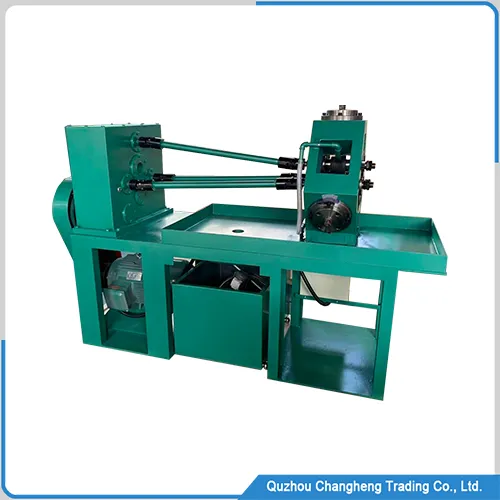

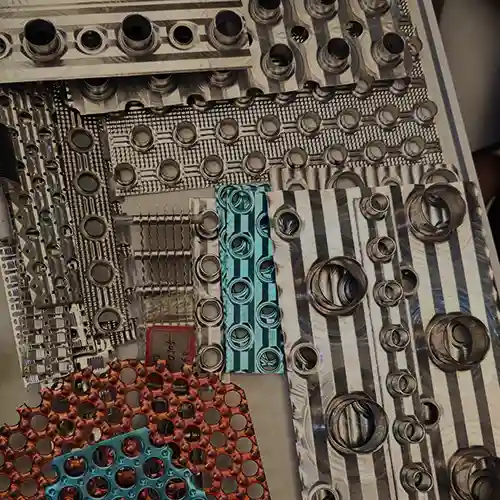

- Fin stamping machine: This machine produces fins for condensers.

- Fin mold: It is uses in conjunction with stamping machines to produce fin products

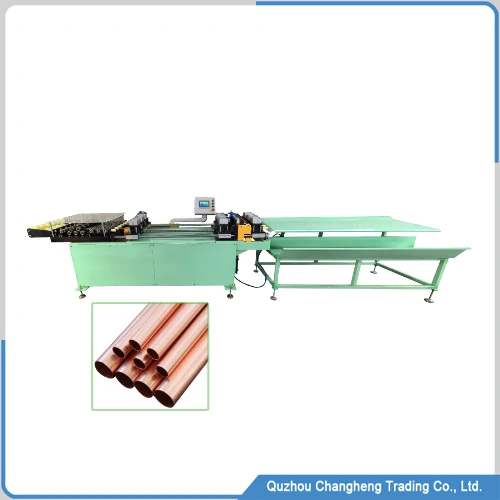

- Copper tube straightening machine: This machine straightens coil copper tubes and then cuts them to length

- Vertical expansion machine: It expands copper pipes and tightly combines fins

- Convenient expansion machine: It is another type of expansion machine suitable for producing large-sized condensers

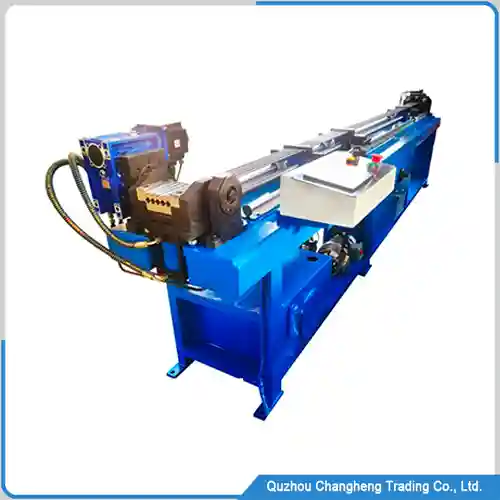

- Bending machine: It bends copper pipes into the shape of hair clips

- Workbench: The core requires this workbench to assemble copper pipes

- Reflux tube machine: The U-shaped tube is connect to a hairpin tube

- Core bending machine: The condenser of a household air conditioner needs to bend the entire core,

- Flame welding machine: The joints of copper pipes need to be welding to seal all copper pipes completely

- Leakage testing machine: All condensers undergo leak testing after production is complete

| No. | Machine name |

| 1 | Fin stamping machine |

| 2 | Fin mold |

| 3 | Tube straightening machine |

| 4 | Vertical expansion machine |

| 5 | Convenient expansion machine |

| 6 | Bending machine |

| 7 | Workbench |

| 8 | Reflux tube machine |

| 9 | Core bending machine |

| 10 | Flame welding machine |

| 11 | Leakage testing machine |

Condenser production line features

1. Stamping machines are high-speed production modes, with a maximum speed of 250 presses per minute. This speed can meet the needs of large-scale production.

2. Most machines use the latest technology, servo motor drive, to ensure product quality and accuracy.

3. This condenser production line can flexibly adapt to products of any size; whether your condenser is used in home AC or industrial fields, it can perfectly adapt.

4. The critical components of the fin mold are hardened by vacuum quenching, which has good wear resistance and service life,

5. Each device has a structural design with replaceable molds, making producing condensers or heat exchangers of multiple sizes easy.

Condenser production line machines

Service and Suggestions

1. There are many different types of condensers, and it is difficult for a new factory to produce all of them. Therefore, we recommend that your new factory only produce the most suitable and profitable condensers.

If you master all manufacturing technologies in the future, you can produce more models to expand your business. This cyclic and gradual working mode will be helpful for the factory’s development.

2. The condenser production line requires a lot of equipment, but not every machine is necessary. For example, if you need equipment to manufacture reflux pipes, you don’t need to purchase it,

You can directly purchase U-shaped return pipes, a very cost-effective business. It reduces investment and eliminates the need to bear manufacturing risks and material losses.

3. Leak testing machines are essential, but besides helium detection equipment, detecting leaks in water is still one of the most effective methods,

wechat

wechat