Machine Overview

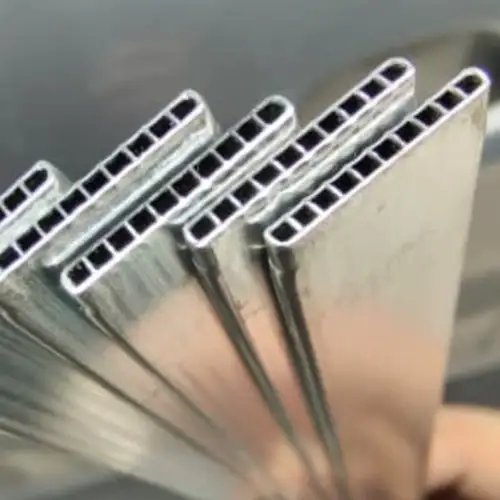

This is a flat tube testing machine for radiator, which is used to check the pressure resistance reliability and welding quality of aluminium tube. This is one of the key equipment for aluminum brazing type radiator production. It uses a pneumatic hydraulic booster pump to output pressure, and the maximum pressure can reach 80 mpa. Whether your flat tube is of type 0, type B, or hourglass type, this machine can meet all the testing requirements

The clamping tool adopts a flexible structural design to test different types of flat tubes without the need for additional cost replacement tools. This design can save a lot of costs and time for tool replacement, which means that the machine does not require additional cost expenditures during the testing process

Technical parameters of tube testing machine

| ITEM | DATA |

| Tube wall thickness | 0.2-2.0 mm |

| Short axis | 1.3-3mm |

| Burst pressure | 50 MPa |

| Measurement accuracy | ≤ ± 0.5%FS |

| Ambient temperature | room temperature |

| Work Medium | water emulsion hydraulic oil |

| maximum Length | 800mm |

| Control mode | automatic control manual control (optional) |

Working principle of the Tube testing machine

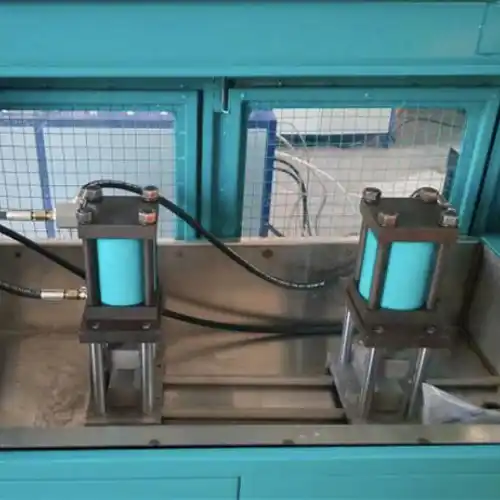

The main power source of this machine comes from compressed air, which drives the hydraulic booster pump to output sufficient pressure. The pressure regulating valve controls the pressure and outputs it smoothly to the testing tool

The test tool is drive by a hydraulic cylinder. During the test, the two tools clamp the two ends of the flat tube and transmit the pressure to the inside of the tube, and then the pressure will remain for a period of time

The pressure curve will be displayed on the screen to check whether the tube has leakage. During this process, the aluminium tube usually expands, which is a normal phenomenon

In the second stage, the tube testing machine will slowly increase the test pressure until the aluminium tube breaks, and record the maximum bearing pressure of the aluminum flat tube,

During the testing process, the computer of this machine will record all test data, including changes in testing time and pressure, as well as the peak value of the highest pressure. It can also automatically produce visual reports, output them in PDF and Word formats, print the reports directly, or send them via email

Aluminum tube testing machine Characteristics

- High degree of freedom control

Users can set diversified test conditions according to the characteristics of aluminium tube, such as limit pressure test, pressure maintaining test, blasting test, etc., or first pressure maintaining test and then automatic blasting

- No additional testing costs

The tube testing machine has good versatility of tools. No tools need to be replace or adjust during testing, so the user does not need to pay additional costs

- Automatic pressure compensation

During the experiment, when the tube expands, the pressure will drop, the machine will automatically compensate the pressure to the set value, and then continue the pressure maintaining test. If the tube breaks, the pressure will drop rapidly and the machine will automatically stop

- Built in printer

The testing process is control by an industrial computer and has a built-in printer. When the testing is completed, the machine will automatically generate a test report, which will be printed through the built-in printer,

Tube testing machine working video

Tube testing machine control system

The control system is an industrial computer install on a workbench and equipped with an Electric Transfer Chair, allowing engineers to sit here and focus more on their work.

The aluminium tube testing machine adopts the latest generation of sensors. The data it collects can be converted into numerical values at a high speed and transmitted to the computer display screen for display through the data line

The data analysis software has multiple built-in file templates, which engineers can use to quickly generate test reports and improve work efficiency

Application of the machine

In the industrial production process, it is necessary to conduct pressure test on tube to ensure that the design and manufacturing quality of products meet the expected effect. This tube testing machine is designed to meet this demand. Here are some examples of the application of this machine

- In the HVAC industry, circular copper pipes are production using extrusion technology. Due to the continuous rise in the price of copper materials, the wall thickness of copper pipes is becoming thinner and thinner. Therefore, this machine is need to test the reliability of copper pipes

- The aluminium tube of the automobile condenser uses a microchannel structure. Because the condenser has a high working pressure, it has high requirements on the quality of tube, so this tube testing machine is one of the appropriate testing equipment

- There are many types of tube of the engine radiator, such as type 0, type B, and hourglass. The wall thickness of these tube is only 0.28mm. In order to ensure the reliability of high-frequency welding, radiator tube need to be tested for bursting pressure every hour during production

wechat

wechat