Brief introduction

The heat exchanger aluminum fin machine is an efficient production equipment with a unique design. The cam drives two plates to move up and down.

It is the most important equipment for producing aluminum heat exchangers. It has a high production speed and a well-compatible mold exchange function and can perform fully automated production.

We can provide users with reliable production equipment and a full range of services, including fin mold design of any size, machine installation, and training.

Aluminum Fin Machine Technical Parameters

| ITEM | DATA |

| raw material | iron foil stainless steel titanium alloy aluminum copper foil |

| Foil thickness | 0.05-0.5 |

| Max. Speed | CHANG HENG |

| Control | PLC |

| Cutting speed | 60 times/min |

| Touch screen brand | Mitsubishi |

| Machine brand | CHANGHENG |

| certificate | CE |

Aluminum fin machine advantage

Our aluminum fin machine has significant advantages in producing industrial plates and aluminum bar heat exchangers over other equipment solutions. Let’s give a few simple examples

1. This complete production line can achieve fully automated production. Thanks to the servo motor controlling the length of the fins, it can produce high-consistency

2. The machine adopts a 5.5kw motor, which outputs strong power. Whether your fin material is aluminum, copper, iron, or stainless steel, the machine can quickly produce them

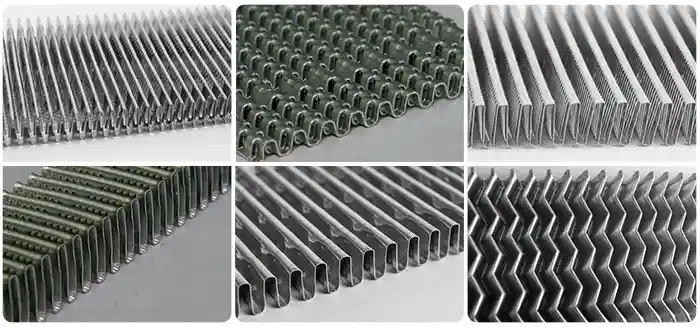

3. The mold of this machine is independently designed, and users who want to produce fins of different shapes only need to replace the pressing mold at a low cost

4. If you are looking for a special kind of fin, we accept custom orders for any shape of fin.

About the fin machine

We are a fin machine factory from China. This machine can produce fins made of different raw materials such as aluminum, copper, stainless steel, titanium alloy, etc,

Our factory accepts customized fin molds of various shapes, such as serrations, waves, straight lines, blinds, etc

This machine is widely used in the military industry, ship manufacturing, and aerospace fields

Aluminum Fin Machine Factory Video

Our Success Stories

Q & A

A: Yes, it can produce copper and various metal materials such as stainless steel 304, titanium alloy, iron, etc.

A: Our fin machine has been improved by designing some positioning for the mold, which can save much mold replacement time. The current mold replacement time is about 30 minutes.

A: Our machine is already equipped with a fully automatic lubrication system.

wechat

wechat