furnace brazing process outline

This is an aluminum furnace brazing process using atmosphere protection, which can produce brazing aluminum products on a large scale and has achieved a reduction in production costs, With the continuous development of industry, this aluminum brazing process has been widely used in various fields of aluminum products, such as automotive radiators and condensers Industrial aluminum plate and bar heat exchangers, aluminum pipes for air conditioning systems, and other parts that require welding, etc

We have 19 years of work experience in this field, and in the first 3 years, no one was willing to provide us with technical support. Our factory encountered many technical problems that could not be solved. After many years of unremitting efforts, we continuously broke through technical barriers, and now we are a leading technology-oriented company in China, Today, I will introduce some details of this aluminum furnace brazing process to you, hoping it will be helpful to you.

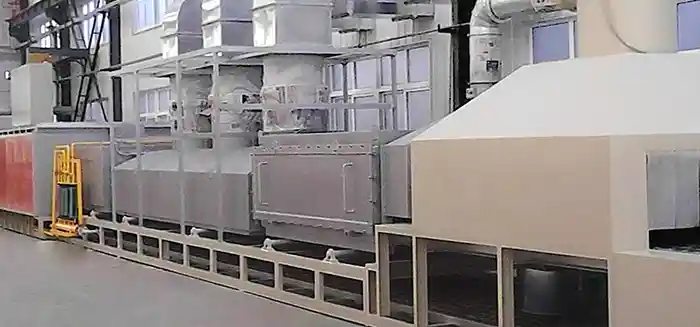

furnace brazing process display

1, Defatting

This process involves purifying the grease on the surface of aluminum products through high-temperature purification, which is suitable for evaporators and condensers, Some factories do not require a degreasing process, but instead use ultrasonic cleaning of the entire aluminum core to achieve optimal surface cleaning of the aluminum core

2, Flux spray

This is an essential process for every aluminum brazing product, and all aluminum products must be sprayed with NOCOLOK flux, High temperatures can melt the brazing flux to achieve the best welding effect

Note: The NOCOLOK flux used in this furnace brazing process is an essential material

3, Drying products

Because spray NOCOLOK flux contains a lot of water, all water must be evaporated before entering the brazing process, which is the most important process in the entire welding process

Warning: If the moisture is not dried, this is a fatal defect and cannot proceed to the next step

4, furnace Brazing process

This is a very complex area that usually requires precise temperature control. The entire brazing tunnel requires nitrogen protection, and external air is not allowed to enter during the entire brazing process, Some products require specialized tools for fixation or placing aluminum products on the tools

The highest temperature here is about 635℃, and the lowest can be 590℃. It can be adjusted appropriately according to the size of the product to achieve the best brazing effect

5, Wind cooling

When the aluminum product is welded, there is still a high temperature of about 250℃ on the surface of the product. A fan is needed to distribute this excess temperature outdoors to maintain a suitable temperature for the entire production workshop

furnace brazing technology data

| name | data |

| Technology type | CAB brazing |

| Gas | Nitrogen |

| Max temperature | 650℃ |

| Design temperature | 750℃ |

| flux brand | NOCOLOK |

| Cooling type | air-cooled |

furnace brazing process video

Troubleshooting

A: The furnace barzing process of electric heating and natural gas heating brazing furnaces is the same

A: The aluminum head plate of your aluminum radiator has not undergone ultrasonic cleaning, and the grease on its surface is not thoroughly cleaned.

A: The temperature in the brazing area is too high, please lower the temperature appropriately.

A: Check the fins of your radiator core. If it is intact, please check the quality of the aluminum tube. If the fins disappear, your brazing temperature is too high.

A: There are many reasons for this quality issue, which need to be eliminated one by one, 1, Insufficient nitrogen or insufficient nitrogen purity. 2, The surface of aluminum products has moisture and has not been thoroughly dried. 3, Quality issues with brazing flux. etc

A: There are some differences in the production process between it and the car radiator. You can contact our engineers for more furnace brazing process details

A: The flux spraying on the head plate is uneven, or the temperature in the brazing area is too low.

A: The side panels assembled with the core are not based on the brazing shrinkage ratio.The quality issue caused is not related to the brazing process

A: Yes: It requires.

wechat

wechat