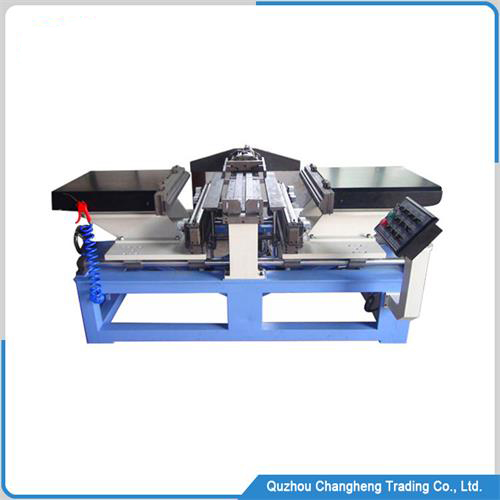

Machine Description

The Condenser tube grooving machine cuts the manifold’s slots. Servo motors control the X and Y-axis movements, while a regular motor drives the Z-axis.

This machine has 4-6 workstations and can cut 4-6 condenser headers simultaneously, greatly improving work efficiency.

The cutting blade material is high-hardness tungsten steel, which not only cuts without burrs but also has a long service life,

The blade’s side has an automatic volatile oil lubrication device, which has significant advantages over traditional liquid lubrication.

Machine quick details

- name: Condenser tube grooving machine

- Workpiece specification: D Type/ Round Type Manifold Pipe

- Baffle Hole: as per the customer’s requirements

- Slot Quantity: Customers set themselves

- Precision tolerance range: Per customer’s requirements

- Pipe Processed per time: 1-5 pcs/time

- Operation method: Manual loading-Auto cutting-Manual unloading

- Production capacity: about 1400 pcs/Hour

- Drive mode: Servo & Pneumatic

- Overall dimension: 1800*1500*1700mm

- Weight: 1.5T

- Power Supply: 380v / 50Hz

Condenser tube grooving machine working video

Other condenser machines

Condenser tube grooving machine advantage

- This machine can cut any car condenser header tube without additional cost.

- 1400 pipes can be cut per hour, which meets the production needs of most companies

- Allow users to write programs based on the cutting size of the head tube

- Advanced blade lubrication technology keeps the machine’s workbench clean and tidy

- Can quickly replace blades to meet different condenser header Tube sizes

- There are isolation doors installed on the left, right, and back of the machine, and the running time of the equipment will not affect the work of others

- The equipment has error-prevention devices. When workers install the wrong condenser round tube, the machine will give an alarm prompt

- An infrared sensor is installed at the position of the machine door. When someone approaches while the machine is running, it will stop urgently for absolute safety.

Q & A

A: Our machine has a 12-month warranty and provides free technical support for life.

A: It can only cut the car condenser header tubes.

A: The maximum length is 800mm, and we can customize a larger size for you.

wechat

wechat