Product Description

This temperature tracker is an industrial instrument that collects temperature data, converts it into digital signals, and transmits them to a computer. Engineers can use this temperature data to improve production processes and continuously optimize production quality.

This instrument has multiple temperature acquisition channels, which means it can independently test temperature data from different locations at the same time. It also has a WIFI transmission function. The computer is connect to the WIFI signal of the temperature tracking instrument, and the computer can check the real-time temperature changes online.

Features of Temperature tracker

Built-in lithium battery

It has a built-in lithium battery that can be charged and reused repeatedly. It can be used continuously for 6-8 hours on a single charge, so you won’t be anxious about power shortages during temperature testing.

Independent data storage

This temperature acquisition instrument has a built-in storage disk, which automatically stores the temperature data of each channel when it starts running. It displays the changes in time and temperature in the form of a curve graph.

High precision resolution

The highest accuracy of the instrument’s temperature collection is 0.1 ℃, and it can collect high and low temperatures while ensuring the accuracy of the data.

Compact volume design

The volume of this temperature acquisition instrument is very compact, with a high-precision integrated circuit board inside. This design ensures data accuracy and normal operation in high temperature environments.

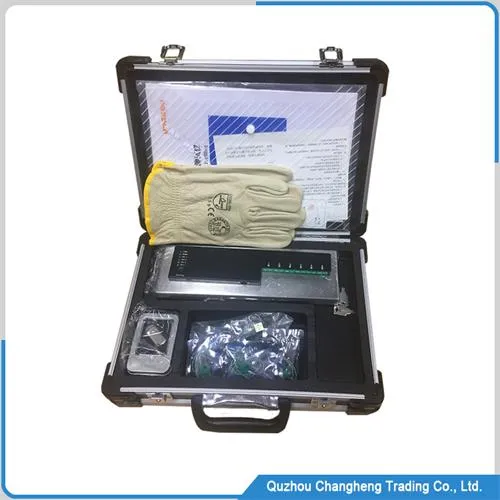

Temperature tracker Insulated box

This insulation box is made of SS304 material as the outer shell, formed by the CNC bending process, and the connecting gaps are welded. The interior is filled with high temperature resistant material.

The size of the insulation box customize according to the user’s usage environment. The higher the temperature used, the larger its size will be to ensure the normal operation of the temperature acquisition instrument.

The connection between the top and bottom of the insulation box is a quick release buckle, which can be quickly open and lock to ensure work efficiency during use.

Temperature tracker advanced function

1. The instrument has a built-in WIFI signal source, which can connect to a computer to view temperature changes online.

This innovative technology is very helpful for users, as engineers can intuitively understand product changes in high-temperature environments and make targeted process improvements to improve production efficiency and product quality.

2. This temperature acquisition instrument has professional software that can be installed on a Windows system computer.

The software is available in both Chinese and English and can view temperature data online and check the complete temperature data. It can also quickly output PDF files or print them as customs declarations.

Temperature tracker working video

Temperature tracker User flow

1. First, check the battery level. If the battery level is below 30%, it must be charge before using it

2. Press the start button on the instrument, check that the WIFI signal can connect normally, install K-type temperature acquisition cables, and place one end of each cable in different positions on the product

3. Install the instrument into the insulation box, close the insulation box, and lock it to prevent temperature from entering the interior of the insulation box,

4. Place the insulation box and product on the conveyor belt of the furnace, simulate the normal production state, and collect all temperature data,

5. When it completes the temperature collection task, the Temperature tracker instrument needs to be immediately taken out of the insulation box to avoid damage from high temperatures

Technical indicators

- Thermocouple: K-type thermocouple

- Sampling interval: 0.05-600Sec (software setting)

- Record duration: 120000 points/channel

- Resolution: 0.1 ℃

- Temperature measurement range: -100-500 ℃ or 0-1200 ℃

- Temperature measurement accuracy: ± 1.0 ℃

- Total power: ≤ 75mW

- Working voltage: 3.3VDC

- Battery: Rechargeable battery

- Working mode: real-time monitoring, temperature recording

- Connection method: RS232/USB WIFI

- Software language: Simplified Chinese, English

Precautions of Temperature tracker

1. After using the insulation box once, it is necessary to wait for it to completely cool down before using it again. This is to protect the normal operation of the instrument better, as high temperatures can cause the lithium battery to fail, which can result in temperature collection stopping

2. This instrument can store 16 sets of temperature data for testing. For data security, the test data will not be overwritten, so you cannot test the 17th temperature data set. Therefore, you must manually clear the old data before continuing to use it

3. It is best to turn on the instrument for WIFI connection and data transmission before testing to ensure that it can operate normally. This will greatly improve the effectiveness and safety of the work before testing

Summarize

This temperature collection device not only has an advanced WIFI transmission function but also a reliable insulation box to ensure its normal operation. The instrument includes software in two languages and can be using on Windows computers,

This instrument is uses in the high-temperature field. If you are looking for this type of equipment for temperature testing to improve the quality of your products, you can contact us for more details.

wechat

wechat