Machine Overview

The aluminum heat exchanger machine is composed of various equipment with different functions. Each equipment completes different production tasks, such as aluminum brazing furnace, aluminium fin production machine, brazing flux spraying machine, aluminum core assembly machine, and other necessary equipment. This article mainly introduces which machines are required for normal production in a plate and bar type heat exchanger factory. Let’s start.

What is a plate and bar type heat exchanger

Plate and bar heat exchangers are very important components in modern industrial manufacturing. They have efficient heat transfer capabilities and can withstand working pressures of 1.5 MPa. They are widely uses in almost every industry, such as ships, aerospace, new energy, nuclear power, and industrial manufacturing.

Each component of the heat exchanger is made of aluminum material, which is assembled like building blocks to form a properly sized aluminum core. The aluminum core is then subjected to high-temperature aluminum brazing, followed by manual welding of the aluminum tank for high-pressure sealing testing.

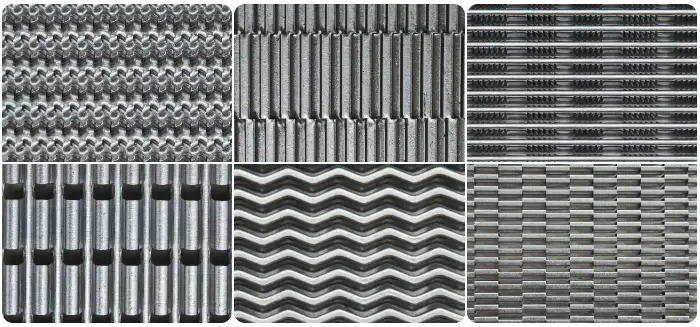

Heat exchanger fin machine

This is a fully automatic production equipment for aluminium fin. One worker can supervise many machines to produce at the same time. The fin mold adopts modular design. The advantage of this design is that it can replace the mold at low cost, produce aluminium fin of different shapes and sizes, and effectively reduce the production cost of the factory

In the production process of the heat exchanger, the dimensional accuracy of the fin directly affects the quality of the aluminum core, such as the aluminum core will leak during brazing, or the aluminum core cannot withstand the high-pressure working environment,

In order to solve these problems, this fin machine adopts high-precision manufacturing technology to effectively control the dimensional accuracy of aluminium fin and meet the high-precision requirements of aluminum core assembly of heat exchanger

Vacuum aluminium brazing furnace

The vacuum furnace is one of the most important equipment for the production of aluminum heat exchanger. The aluminum core is brazing at a temperature of about 620 ℃. It will weld all aluminum parts at one time. This equipment is also the most technologically advanced in the entire production process. It must be driven by an experienced engineer

This machine is the most expensive equipment in the plate and bar heat exchanger factory. Some small-scale production factories use CAB type brazing furnace, and its price will be much cheaper. However, the production technology of this brazing furnace requires aluminum plates to be spraying with flux

If you don’t know which production technology is more suitable for you, you can contact our engineers for more details and necessary technical support

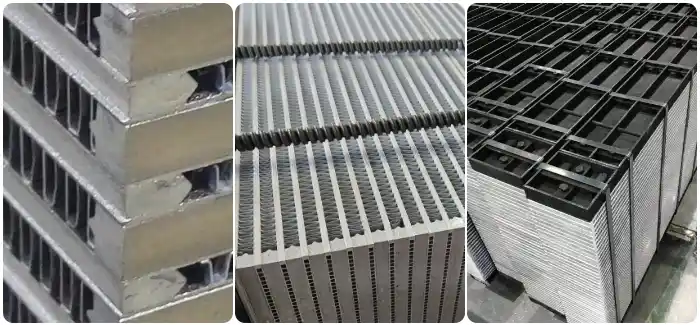

Heat exchanger aluminum core assembly machine

The function of this heat exchanger machine is to assemble aluminum cores. It is driven by a servo motor to adjust the working size of the machine. During the assembly of aluminum cores, the machine does not consume electricity, making it a very energy-saving device. Almost every heat exchanger factory cannot do without this equipment

The heat exchanger factory needs to produce various sizes to meet the needs of customers. In order to meet the production needs of multiple sizes, this machine can freely set the working size without adding any additional costs. Simply press the control button to easily set the required size, and any worker can operate it without undergoing complex training

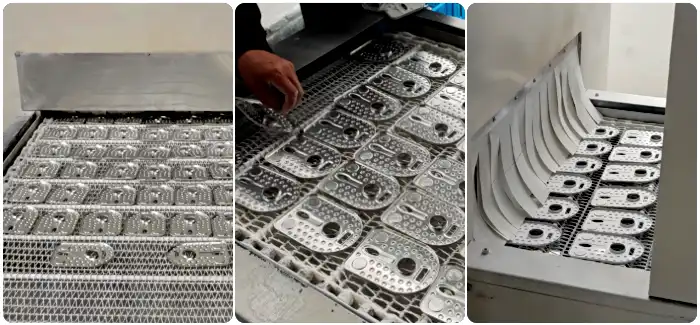

Fulx spraying equipment

This machine is useing to spray aluminum plates with flux. It is an automatic production equipment. Workers only need to put aluminum plates on the chain. This machine will automatically degrease aluminum plates, spray flux, dry, etc. Note: each aluminum plate needs to be spraying twice

If your factory has a vacuum aluminum brazing furnace, you do not need this machine to participate, because aluminum materials do not need to be spraying with flux in a vacuum environment

Other heat exchanger machines

A complete heat exchanger factory also requires other machines, such as argon arc welding machines, air compressors, aluminum profile cutting machines, etc. These machines are standardized equipment that can be easily purchased in the market We won’t introduce them here

The processing of aluminum profiles requires a bench drill or milling machine, which is a key equipment for producing aluminum tanks

More heat exchanger machines

Our range of machine services

- Size customization service

Due to the wide range of applications of heat exchangers, there are many sizes and types available. In order to meet the production needs of such multiple sizes, our equipment can perfectly solve this problem without the need to replace tools and molds, and does not require a large amount of capital investment

- technical training service

Our engineers have 20 years of work experience in the aluminum heat exchanger industry. Whether your heat exchanger is applie in the generator industry, marine and aviation industry, or other industrial fields, we can provide excellent technical services to help you manufacture industry-leading product quality in a short period of time Not only that, we also provide up to 2 years of online technical support to safeguard your high-quality production

- Excellent after-sales support

Our team is all from the mechanical manufacturing industry, and they have rich work experience and are very professional in the aluminum heat exchanger industry. 90% of the problems found in the production process of heat exchangers can be solve online by our engineers

Q & A

A: If you buy all the machines from us We provide free machine installation services and aluminum brazing technology training.

A: The fin machine can produce both fins only by changing the mold.

A: Our machines are making according to customer requirements, and the most cost-effective size is usually 800*800*1200mm.

A: Each machine is one, so it can produce 3000-5000 heat exchangers per month.

wechat

wechat