Machine Overview

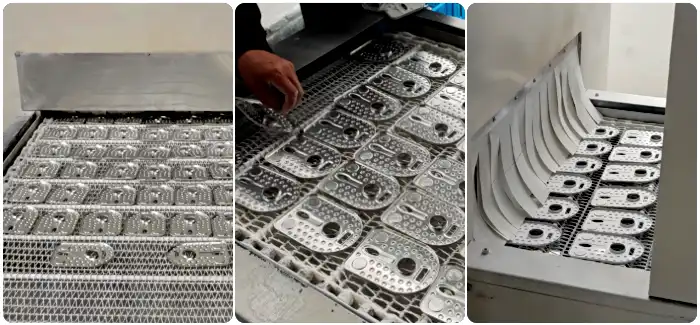

This is a continuous production aluminum brazing flux spraying machine, which is very suitable for large-scale production in modern factories. This production line is composed of preheating, automatic spraying, flux drying, and cooling. Workers only need to arrange the product neatly and then take it out at the end. The machine automatically completes the spraying process.

The spraying device has a stirring, a high-pressure spray gun, a linear moving device, etc. Servo motors control the linear moving parts, and the flux is evenly spraying on the surface of the parts through intelligent algorithms. The spraying thickness is controlled at the nano level, and the speed is used to control it precisely.

This machine is widely use in modern industrial production, especially in the automotive industry, such as Car evaporators, condensers, transmission oil coolers, etc., battery cooling plates for battery cars, etc. They all need this machine for flux spraying.

Advantages of the Aluminum brazing flux spraying machine

- Precise control of flux thickness

By controlling the moving speed of the servo motor and the air pressure of the high-pressure spray gun, the thickness of flux spraying can be achieved at the nano level, and its thickness can also be precisely controlled.

- High-efficiency production types

This aluminium brazing flux spraying production line is a continuous production mode, which not only improves production efficiency but also realizes large-scale production and reduces production costs. Mass production can be completed with only two workers.

- Flux recovery device

The closed spray space design effectively recovers the flux back to the mixing tank and uses it again. This process is automatic without any additional production costs.

- Multi-layer thermal insulation design

The tunnel of this spray production line adopts a multi-layer thermal insulation design, which not only effectively reduces heat loss but also ensures the comfort of the production environment.

- Beautiful appearance craftsmanship

The appearance of this machine is a 2mm metal plate cut by a Laser Cutter, then bent to the required size, and finally painted on the metal plate. The color of the machine has reached the automotive appearance level.

Aluminum Brazing Flux Spraying Machine Technical Data

- Production line use: flux spraying

- Appearance color: Default off-white

- Tunnel Height: 200mm (Customized)

- Tunnel width: 600mm (accept customization)

- Production speed: 0-1800mm/min

- Table height: 800mm

- Flux type: NOCOLOK

- Control system: PLC and touch screen

- Language: Chinese and English

- Transmission method: stainless steel mesh belt

- Spraying method: high-pressure spray gun

- Spray Control: Servo Motor

- Heating method: thermocouple

- Power supply: 380V/50Hz

- Voltage: 60Kw

Aluminum brazing flux spraying machine working video

Transportation and installation

The packaging produced by this flux spraying is wrapped in a layer of plastic film, and then put into a 20-foot container and fix it in the container. Because its size is just in line with the 20-foot container, there is no need for wooden box packaging.

We will send this aluminum brazing flux machine to any port in China, and will cover all shipping costs incurred in China, handle every detail properly, and provide all necessary shipping official documents.

When the machine arrives at the seller’s factory, we can send engineers to install the machine and train the buyer’s engineers to use the machine smoothly. However, during installation, the buyer’s engineers need to provide necessary assistance.

This aluminum brazing flux production line has a cooling fan, which requires a chimney to direct heat to the outside to maintain a suitable temperature in the factory’s workshop. In some countries with strict environmental protection, there may be some troubles, and these problems need to be process by the buyer.

wechat

wechat