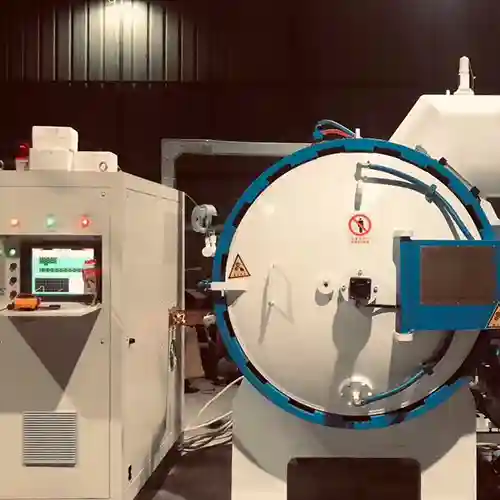

This vacuum heat treatment furnace is industrial production equipment with a vacuum environment and a wide range of applications, such as military, shipbuilding, digital, pharmaceutical, and aerospace.

Our engineers and heat treatment experts bring decades of experience into the design, providing first-class manufacturing with advanced industrial equipment and skilled technical personnel. The vacuum heat treatment furnace has become one of the most cost-effective, energy-saving, and technologically advanced.

Precise temperature control is one of the necessary conditions for the vacuum heat treatment furnace to meet the manufacturing requirements of demanding parts. The furnace’s control system uses a 10.1-inch touch screen as a human-machine interaction and a visual operation interface. New engineers only need simple training to master all temperature control.

We accept customized furnaces of any type to meet the requirements of different customers. We can provide excellent solutions if you need aluminum brazing, stress relief, heat treatment, stainless steel brazing, a sintering furnace, normalizing, annealing, or tempering.

Technical Data

| ITEM | DATA |

| Power supply | 380v/50Hz customizable |

| Max temperature | 650-2000 ℃ |

| Working size | customized |

| Vacuum pressure | customized |

| Delivery time | 60-120 days |

vacuum heat treatment furnace application

- aluminum brazing: Mainly welding multiple aluminum parts together

- Annealing: Eliminating residual stress inside the material

- Tempering: A heat treatment process in which the workpiece is quenched and held for some time before cooling to room temperature.

- Sintering: Powder or metal is sintered under vacuum conditions in ceramic billets

- Stainless steel brazing: Multiple stainless steel parts are welded together in a vacuum environment

- Stress relief: reduces residual stress in the structure of parts and reduces the risk of dimensional changes

vacuum heat treatment furnace video

WHY CHOOSE US

- Advanced equipment manufacturing process

- Excellent engineers and experienced experts in vacuum heat treatment furnaces

- Globally competitive prices

- A comprehensive after-sales service team

- Visual control system for precise temperature control

- Accept customized services for any vacuum furnace

Q & A

A: Of course, please get in touch with our engineers so you can easily access our catalog.

A: The maximum temperature of an aluminum brazing furnace is usually 750℃ Celsius, The actual usage is approximately 630℃.

A: We can accept size customization; you can contact us for more details.

A: We can design a control system to meet your power supply needs.

wechat

wechat