Machine summary

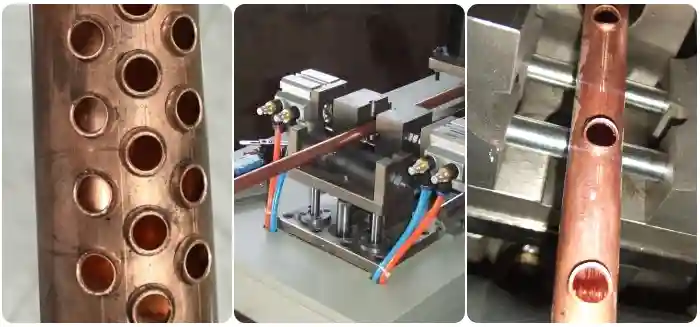

The copper tube punching machine is a highly automated HVAC equipment designed specifically for opening holes in copper heat exchangers. Its core function is to drive the clamp to rotate through a servo motor, and the tool pierces the copper pipe from the inside to the outside, accurately arranging each hole to form a flanged circular hole.

The machine adopts a unique design. The punch applies pressure from the inside of the copper tube, then forms a standard round hole, and completes the required shape in one go, without the need for a second processing, which effectively improves production efficiency.

Moreover, this pipe punching machine can process multiple rows of holes simultaneously for a tube, and the tolerance of the spacing size of each hole is controlled to within 0.01 mm.

This high-precision capability is achieved through a 2-axis servo motor drive, which features a rotating function and can simultaneously complete various actions, including positioning, tightening, feeding, and punching holes.

The technical parameters of the copper tube punching machine.

- Applicable pipe materials: copper tubes and aluminum tubes

- Maximum copper pipe diameter: Φ65mm

- Minimum copper pipe diameter: Φ12.0mm

- Copper pipe wall thickness range: 0.3 – 1mm

- Maximum processing pipe length: 1580mm

- Minimum hole diameter: Φ5.0mm

- Hole inner diameter precision: ±0.05mm

- Minimum distance between two holes: 15mm (taking Φ8mm holes as an example)

- Flange height: 1.5mm- 2mm

- Tube verticality: ≤ 0.1mm

- Feed axis position accuracy: ±0.10mm

- Rotation axis position accuracy: ±0.10°

- Feed speed: 600mm/S

- Rotation speed: 270°/S

- Control system: PLC + HMI

- Servo system: Mitsubishi

- Transmission: THK

The advantages of the copper tube punching machine

High-precision equipment

The core parts of this machine are processed using CNC machine tools and have undergone high-temperature quenching treatment. The parts responsible for rotation have been polished, which further increases their precision. This ensures that the precision error of the parts it produces is controlled within 0.01mm.

High-efficiency production

The machine utilizes two servo motors as its primary source of power. It features a unique punch design, which not only enhances production efficiency and economy but also ensures stable control and high-quality output.

Intelligent and convenient operation

This machine integrates a PLC and touchscreen control, enabling fully automatic operation. The number of holes and the arrangement, spacing, and size of the tube are preset by the touchscreen, and it is convenient to store recipes for future use.

Multiple sizes of applications

The components of this equipment are design modularly, allowing for low-cost replacement tools that enhance the machine’s ease of use. It can handle copper tubes with diameters ranging from 12 to 60 mm, a wall thickness of 0.3 to 1 mm, and a maximum length of 1,580 mm. These size ranges can cover more than 90% of heat exchangers in the HVAC industry.

Copper tube punching machine working video

Technical features

- To achieve the precise displacement of the copper pipe, the device utilizes a compact guide rail and a ball screw, arranged accurately, and then controls the movement through a servo motor.

- The control system not only has a PLC and a touchscreen, but also retains physical buttons. It uses three colors – red, yellow, and green – to distinguish different control functions. In an emergency, workers can quickly operate it to achieve a one-key shutdown.

- The machine’s appearance is coated with paint, which not only looks beautiful but also has very high durability. It will not rust in harsh environments for a long time, and always maintains a bright color.

- This machine enables fully automatic production, allowing workers to operate it efficiently without requiring rigorous training. This helps to maintain long-term and stable quality output; even if the workers change, it will not affect the quality of the products.

The application scenarios of the tube punching equipment

This machine, with its numerous advantages including high precision production and automated control, is an indispensable piece of equipment in modern heat exchanger production. Especially in the manufacturing process of large-size evaporators and condensers, fin tubes need to be insertar into large-diameter tubes. The holes of these tubes need to be flanged outward, which allows the fluid to flow more smoothly inside. Therefore, this copper tube hole opening machine plays an important role.

However, with the development of industry and the advancement of manufacturing technology, more and more industries are gradually utilizing this equipment to enhance production efficiency, such as the solar industry, the battery cooling plate industry, and the wind power generation industry. In the future, more industries should utilize this equipment for thin-walled copper tubes.

wechat

wechat