Product Overview

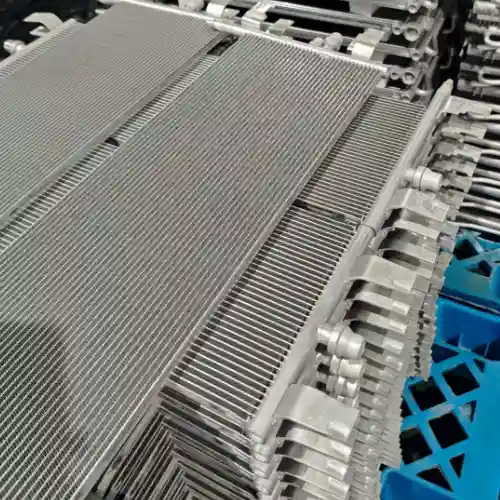

Microchannel condenser is an industrial product, which is composed of microchannel aluminium tube, header tube, aluminium fin and other parts. It is mainly used in the automotive and refrigeration industries. Due to the rising price of copper materials, more and more industries now use this kind of microchannel condenser which is all made of aluminum materials

This type of condenser is usually produced by continuous aluminum brazing process. All parts are welded together at one time, which not only greatly reduces the production cost, but also improves its quality and service life

Compared with the traditional copper tube condenser, it has obvious advantages. It not only has a very high cost performance ratio, but also can greatly save Freon. In addition, its size is much smaller, and it also has obvious advantages in lightweight

What machines to produce microchannel condensers?

Fin making machine

This is a roll forming fin machine, which can mass produce aluminium fin in a short period of time. Its roll mold adopts modular design. Replacing this mold can produce fin of different shapes and different fin sizes

This fin machine is specially designed for the production of condenser. It can freely set the length of fin according to the length of products to meet the production requirements of various condenser

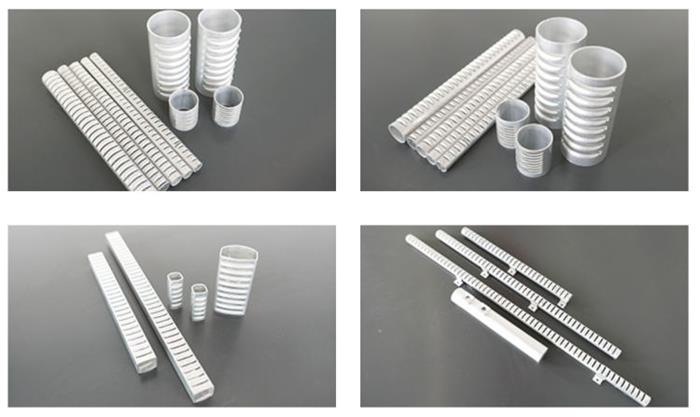

Stamping mold of header tubes

The collector pipe is a round pipe. This tube has high requirements for the stamping die, so the die must be manufactured with high precision, and no waste is allowed in the opening. Moreover, the pitch size error of each hole cannot exceed 0.01mm, so the price of the stamping die will be a little more expensive

The condenser mold adopts the top mold and the bottom mold design. It has multiple guide pillars for positioning, and is equipped with cylinders as locking tools. The mold has a protective device inside, which can be installed on any brand of stamping machine to work

Core assembly machine of microchannel condenser

Assembly of condenser is an important production process. At present, there are many types of machines on the market that can meet this production requirement. The main difference is that their production efficiency is different and the price of the machines is different But the quality of condenser assembly is basically the same

You can check this video to understand the assembly process of condenser. If you are interested in producing condenser and are interested in investing in a condenser production plant in the future, you are welcome to contact us

Aluminum brazing furnace

In the production process of the microchannel condenser, aluminum brazing is the most critical technology. It requires accurate control of temperature and the speed of chain movement, and also needs to spray nocolok flux. But don’t worry. The latest aluminum brazing furnace we provide can achieve fully automatic production. We can train your engineers in a short time to help you solve all problems

All you need to do is tell us the maximum size of your microchannel condenser and how many condenser you plan to produce each month. We will help you solve all other problems

Leakage testing machine

Every condenser needs to pass the sealing test. The test pressure is usually 1.5 mpa. Some OEM factories use helium testing machines. The price of this machine is very expensive, and ordinary factories may not accept its price

Some small-scale condenser factories put condenser in water and then fill compressed air into condenser to visually check whether there are bubbles in the condenser in water. This test method is also feasible, but the production efficiency is very low, and the condenser after testing needs drying

Application field of microchannel condenser

- Automotive industry

The condenser with this structure is widely used in the automotive field. Almost every internal combustion engine car needs a condenser. Now the latest battery cars also need this condenser for air-conditioning refrigeration,

- Home refrigeration and air conditioning

In order to reduce the cost of household air conditioners, there is an air conditioner that only has refrigeration. It uses this micro channel condenser, which not only makes the outdoor air conditioner smaller, but also saves a lot of Freon. However, this air conditioner can only be used in cities that are not cold in winter, because it has no heating function

- Industrial refrigeration machinery

In the field of industrial production, there are many industries that need precise cooling to ensure the stable output of product quality, such as beverage and brewing industries, plastic injection and semiconductor industries. Now more and more industrial refrigeration machines use this condenser as their main heat exchange tool to reduce costs and provide their competitiveness

List of microchannel condenser machines

Advantages of microchannel condenser

- Lightweight and cost-effective

This condenser is made of all aluminum materials, so its weight is very light. Compared with the copper condenser, its price is only 1/3 of that of the copper condenser. As the price of copper materials continues to rise, the price difference will become larger and larger.

- Efficient heat exchange efficiency

The fin of this condenser adopts the design of louver, which has large wind resistance, and the heat transfer efficiency is 32% higher than that of the copper condenser.

- Save Freon

The inner space of the flat tube of the microchannel is smaller. Compared with the traditional condenser, it uses less Freon, and the cooling effect of the air conditioner is better.

- Very suitable for large-scale production

Because of the structural design features of the microchannel condenser, it is very suitable for large-scale industrial production, and the manufacturing cost is very low.

Precautions for the production of microchannel condensers

Sales channels:

If you plan to start the production of microchannel condenser, first you need to consider your sales channels and the price of condenser in your market. Since this condenser has a huge sales market, but the market competition is also very fierce. Some importers buy complete condenser from China, which has a high cost performance ratio, so your sales market and profit should be the first consideration

All investment costs:

A complete factory needs a variety of costs such as machines, factory buildings, manufacturing technology, enterprise management, raw materials, etc. You must accurately calculate the costs and consider the potential risks to ensure that the investment in the factory is profitable. Otherwise, do not start the project, because large-scale production of condenser requires a lot of money, which may put you in debt risk

Aluminum brazing technology:

The key to producing this kind of condenser is the brazing technology. Your mechanical supplier must have a complete aluminum brazing technology and can teach it to your engineers for free or for free. You must fully consider this problem, because once there is a minor control error in high-temperature aluminum brazing, it will cause great losses

Manufacturing cost control:

Due to the rising price of raw materials, in order to reduce production costs, condenser factories in China have realized mechanized production. Although their machines are very expensive, they can reduce the participation of workers and effectively reduce the wage expenditure of workers. However, this kind of automated production is only suitable for large-scale production of single products. Multi model and small batch production, semi-automatic machines are more suitable,

Material control:

In some countries, the industrial base is relatively weak, and it is impossible to buy the required raw materials in the factory. If all the raw materials come from China, this will extend the return time of your funds, which will greatly increase your financial costs and capital pressure. The maximum time for Chinese factories to buy raw materials to sell condenser is about 45-60 days. If your time is more than 90 days, you need to spend more time to control your supply chain management, and shorten the time as much as possible

Other precautions:

I won’t go into details here. If you have decided to start producing microchannel condenser, you can contact our engineers. We have more than 20 years of work experience in this industry, and we can give you many good suggestions for free Let you not make mistakes in this industry

wechat

wechat