Product Description

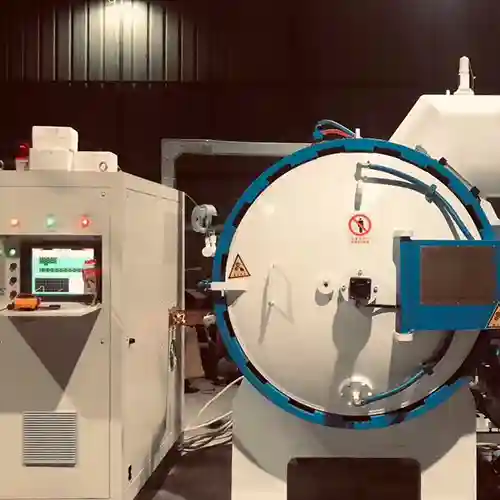

This vacuum gas quenching furnace is suitable for quenching high-speed tool steel, cutting steel, and other alloy steels. It has a convection heating function and can achieve fully automatic stage quenching, tempering, annealing, and other heat treatment processes.

The control system of this equipment adopts PLC control, intelligent and precise temperature control, and the entire quenching process is fully self-controlled, allowing users to customize temperature and vacuum pressure settings. Automatic or manual mode can be freely switched to meet the diverse quenching process requirements of customers

The vacuum furnace already has an abnormal alarm function, which will issue a warning for any violation of operation and prompt the engineer to correct the error

Vacuum Gas Quenching Furnace Technological Process

1, Heat at room temperature to 500 ℃ for 30 minutes, with a vacuum pressure of 6.7*10 -1

When the temperature and vacuum pressure reach the set values, Start the second phase

2, Heat temperature 500℃ to 800 ℃ for 20 minutes, with a vacuum pressure of 6.7*10 -2

When the temperature and vacuum pressure reach the set values, Start the next phase

3, Heat temperature 800℃ to 1000 ℃ for 20 minutes, with a vacuum pressure of 6.7*10 -3

When the temperature and vacuum pressure reach the set values, the Vacuum Gas Quenching Furnace will Start keeping the needles at 1000℃ for 45 minutes

4, Injecting nitrogen into the vacuum furnace chamber, lower the temperature to 40°C in 50 minutes

5, heat the temperature to 180℃ in 10 minutes

6, keep the needles at 180°C for 30 minutes

7, low down the temperature to 40°C in 20 minutes

8, End of gas quenching

This process flow can be set through the touch screen, and the control system will automatically complete each step according to this program

Vacuum Gas Quenching Furnace Technical Parameters

| ITEM | DATA |

| Vacuum pressure | 6.7*10-4pa |

| Control mode | fully automatic |

| Gas | Nitrogen |

| Temperature uniformity | ± 5 ℃ |

| Heating rate | 20℃/min |

| Maximum temperature | 1300℃ |

| Languages | English Chinese Russian Spanish (optional) |

Furnace Structure

The vacuum gas quenching furnace is a horizontal single-chamber structure, consisting of a furnace body, furnace cover, heating chamber, and a forced circulation water cooling device.

The furnace body and cover are double-wall water-cooled structures, and the inner and outer walls are made of stainless steel. There is a gap between the two layers where cooling water flows through,

The front end is connected to the furnace mouth flange, and the rear end is connected to the head. A flange interface is left at the rear end of the furnace body to connect to the air-cooled motor. A bracket is designed at the bottom of the furnace body to facilitate the placement of the furnace body.

The furnace body is equipped with the following openings:

- Opening for evacuation

- Electrode opening

- Thermocouple opening

- Inflatable opening

- Pressure measurement opening

- Safety valve installation opening

- Other auxiliary openings

- Specially designed drainage holes at the front furnace door,

- Specially designed drainage holes at the bottom of the furnace body

wechat

wechat