The pipe bending machine is a device specifically used for pipeline processing, whose main function is to bend copper or aluminum pipes into a hairpin shape. In the production of heat exchangers, pipe bending machines is one of the important equipment. With the development of industry and technological progress, a new type of fully automatic production heat exchanger pipe bending machine has been introduced

Working principle of pipe binding machine

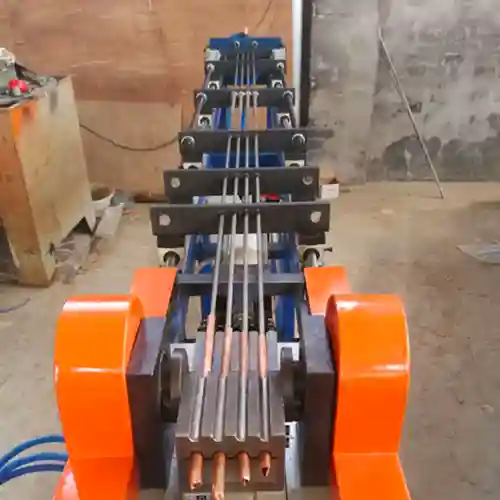

The pipe bending machine is a fully automatic production heat exchanger copper pipe bending machine, which works by controlling the bending axis through a servo motor to achieve the automatic bending of copper pipes. The equipment mainly consists of a servo motor, a bending axis, a positioning system, a push-out axis, and a control system.

The servo motor is responsible for controlling the rotation of the bending axis and the accuracy of the positioning system. The bending axis is driven by a servo motor, and its rotational speed and size can be accurately controlled. The positioning system can ensure the accuracy of the position of the copper pipe to ensure the correct position of the bent copper pipe.

During normal production, workers only need to insert the pipes into the tools on the machine. This equipment will automatically run multiple steps to complete the bending of the pipes. In order to further increase production, we have designed multiple workstations for the machine, which can bend 4-8 pipes at once

pipe bending machine Part Brand

| part name | brand |

| PLC | Mitsubishi |

| Pneumatic accessories | SMC |

| Servo motor | Mitsubishi |

| Electrical accessories | Schneider Omron |

| Touch screen | Delta |

Advantages of pipe bending machine

1, High degree of automation

The tube bender machine adopts automated control technology, which can automatically complete the bending of copper pipes.

2, High precision

The bending axis of the pipe bending machine can accurately control the position and rotation angle of the copper pipe, thereby ensuring high accuracy of the bent copper pipe.

3, High production efficiency

The pipe bending machine adopts a design of multiple workstations and can bend multiple copper pipes at once. This means improving production efficiency and reducing production costs.

4, cost performance

Compared to other suppliers, our machine has a significant price advantage,

5, Energy saving

This tube bending machine uses a servo motor as the main drive, and the waiting time for the motor to stop running means that the machine has very power-saving hardware support

Technical Parameter

| ITEM | VALUE |

| Pipe diameter | 5-12.7mm |

| Wall thickness | 0.2-0.5mm |

| Bending amount | 8 pieces |

| Bending length | 200-3000mm |

| Air source pressure | 0.5~0.6Mpa |

| Pipe central moment | 15-35mm |

| Bending speed | 12 times/min |

| Bending type | U type |

| Power supply | 380V/50Hz 3-phase |

| Total power | 7.5 kW |

Machine Video

Q & A

A: The maximum length of this machine is 3000mm, and we can customize longer sizes.

A: Our regular machine bends 4 pipes at a time, and we can customize the machine to bend 6 or 8 pipes.

A: Yes, this machine is controlled by PLC and has a touch screen.

wechat

wechat