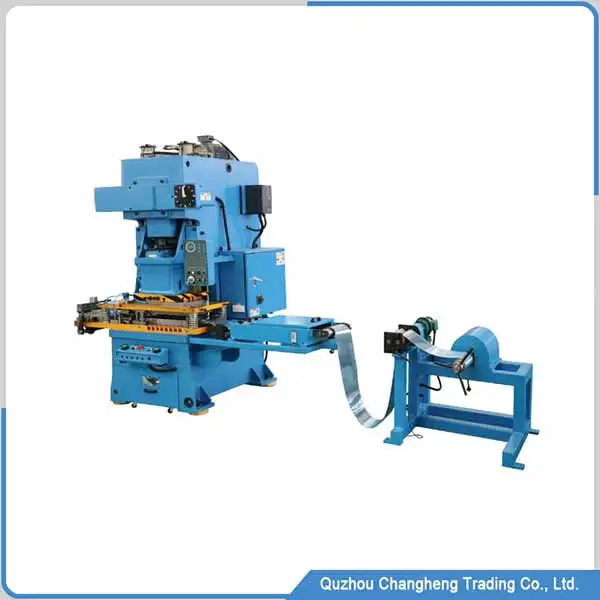

Machine Outline

The heat exchanger fin line press is high-speed equipment made of a unique cast iron alloy, which has high stiffness and impact resistance. In order to ensure the accuracy and stability of operation, the slider of the press adopts a long guide rail and a slider balance device to ensure the stability and accuracy of operation.

The electronic timing automatic lubrication system of the press is installed in all anti-wear components to ensure sufficient lubricating oil during high-speed operation. If there is not enough lubricating oil, the compressor will automatically shut down to avoid damaging the fin line press equipment.

The press adopts a complex and direct control mechanism to ensure the accuracy of slider operation and stop. This equipment can adapt to any requirements of automated production, improve production efficiency, and reduce costs.

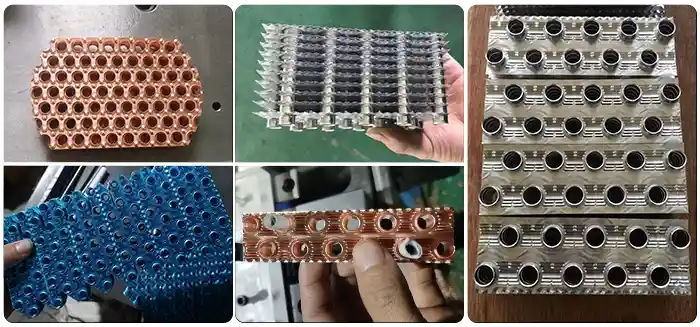

The high-speed heat exchanger aluminum fin stamping production line is mainly used for the production of small precision parts, such as motor stators and rotors, precision electronics, communication, computers, household appliances, and household appliances. These production lines are usually used to produce high-quality products and ensure efficient operation of the production line.

Fin Press Line Usage Method

1, Before starting the device, make sure to disconnect the power and plug the power plug into the power outlet.

2, Turn on the main power switch of the device and wait for the device to warm up for a period of time before using it.

3, Set and use various adjustment devices of the fin line press equipment, such as speed regulating potentiometer and pressure regulator, according to the requirements of specific equipment and the instructions in the instruction manual or operation manual.

4, Ensure that the operating environment of the equipment meets safety standards, such as maintaining air circulation and avoiding dampness.

5, When repairing or replacing equipment components, it is necessary to follow the safety measures and steps in the equipment manual to avoid injury or damage to the equipment.

6, When using equipment, it is necessary to follow the instructions and recommendations provided by the equipment manufacturer to ensure the safety and reliability of the fin line press machine

Applied Range

| ITEM | DATA |

| Raw materials | copper SS304 SS201 aluminum iron titanium |

| Language | English Chinese Russian Spanish Arabic |

| Touch screen size | 7 inches |

| Products | Automotive heaters radiators heat exchangers condensers evaporators Industrial cooling |

Fin Line Press Technical Parameters

- the nominal force of the slider: 450 KN

- Nominal force stroke: 4mm

- stroke: 120 mm

- Distance from slider center to the fuselage: 225 mm

- Pillar distance: 515mm

- Slider bottom dimension: 410*340 mm

- Hole size of die shank: 50*60 mm

- Table size: 825*440 mm

- Travel fixed times: 80 /min

- ravel variable times: 50-80 /min

- Closed height: 270 mm

- Closed height regulation: 60mm

- Diameter of blanking hole: φ150 mm

- Worktable thickness: 110 mm

- distance between the working table and the ground: 800 mm

- overall dimension: 1585*1075*2391 mm

- Anchor bolt distance: 1075*760 mm

- Motor power: 5.5KW

- weight:3550KG

Our success stories

Fin Line Press Machine Video

Q & A

A: The punching force of this machine is 45 tons, and the production speed is 300 times per minute. Your factory floor needs to be reinforced, It can only be produced on the first floor

A: Our fin press lines are packed in wooden cases. In order to smoothly load the machines into containers, we pack the machines lying down

A: Of course, the appearance color of our machine can be customized, but the color may be a little different

wechat

wechat