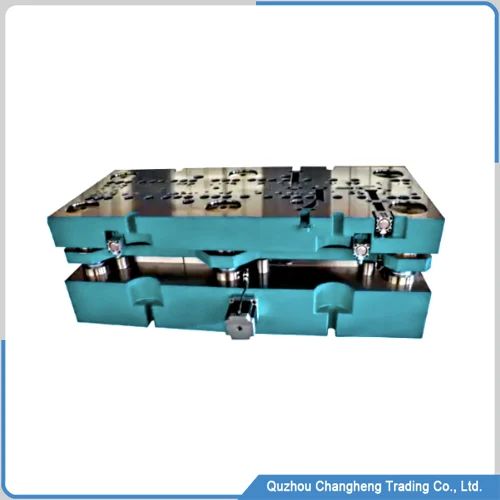

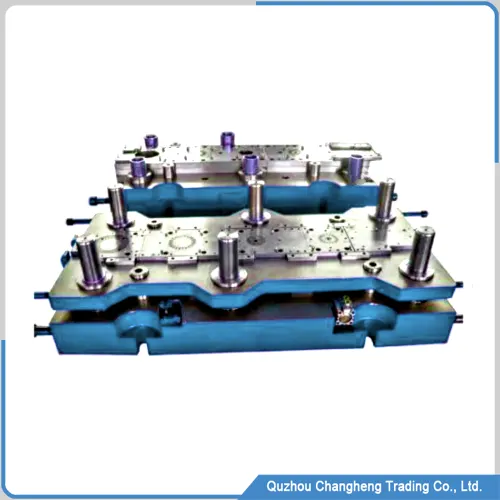

Mold Overview

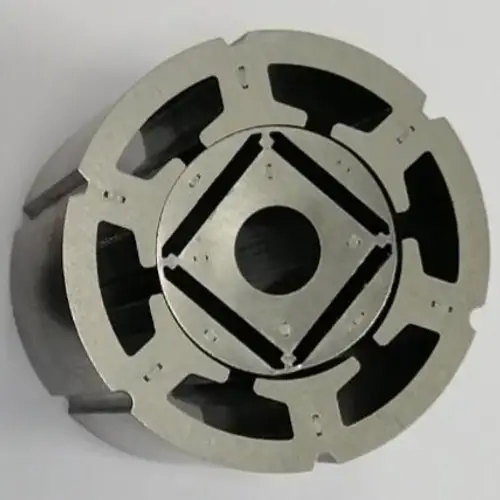

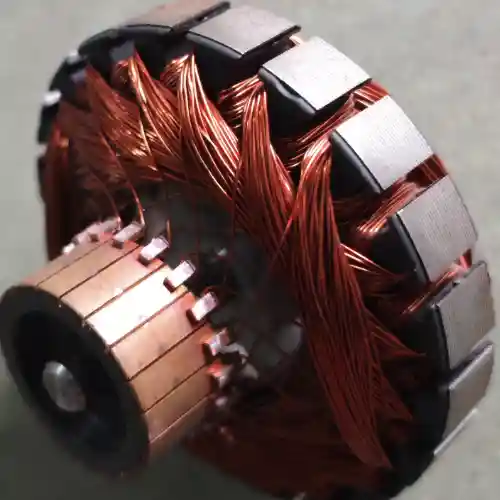

The electric motor stamping die plays a crucial role in the motor manufacturing industry, as manufacturers can produce many motor rotors and stators with high efficiency and consistency.

These molds are usually made of high-strength steel to withstand continuous stamping processes without deformation or damage.

The design of the electric motor stamping die takes into account the fluidity of materials, elastic recovery, and the distribution of forces during the stamping process to ensure the accuracy and quality of the final product.

The key components of the mold are designed independently, and when these parts have slight wear, they can be replaced quickly at a low cost

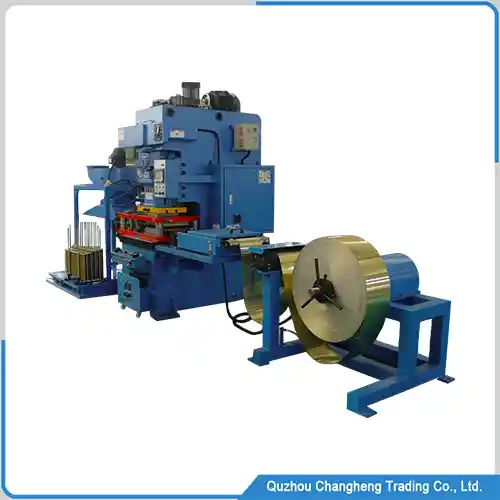

In addition, stamping molds may integrate automated feeding and extraction systems, further improving production speed and reducing manual operations.

By using precise measurement and testing equipment, it is possible to ensure that each component meets strict quality standards.

The advantages of electric motor stamping die

1, High production efficiency:

The automated stamping process can produce a large number of identical parts

2, Consistency and repeatability:

Ensure that the dimensions and shapes of each component meet strict tolerance requirements

3, High material utilization rate:

When designing the mold, the material utilization rate is fully considered, allowing for the simultaneous production of rotors and customization.

4, Easy to maintain:

The key components of the electric motor stamping die are designed independently, making future maintenance very simple

5, Quality control:

The automated production process is easy to monitor and control, helping to detect and solve problems in a timely manner, and ensuring product quality.

Electric motor stamping die data

| No. | ITEM | DATA |

| 1 | Parts | rotor & stator |

| 2 | Working mode | lamination |

| 3 | Production type | continuous |

| 4 | Part material | Iron |

| 5 | Shape | Circular |

| 6 | Mold material | SKH51 Cr12MoV |

| 7 | Appearance | Orange |

| 8 | Workstation | 1-6 optional |

Why choose our mold

1, Rich work experience: Engineers in this field have over 15 years of work experience

2, Independently designed vulnerable parts allow for quick and low-cost replacement of worn parts,

3, The mold can be equipped with a servo motor, and the stator of the special rotor needs to rotate out. We have configured a servo motor for the mold to accurately control the rotation angle

4, High-precision manufacturing, stamping molds are produced using high-precision instruments to ensure the quality of the molds

electric motor stamping die working video

Q & A

A: It can produce laminated rotor and stator types.

A: Normally, delivery can be made within 45 working days.

A: Of course You can choose any color.

wechat

wechat