Overview

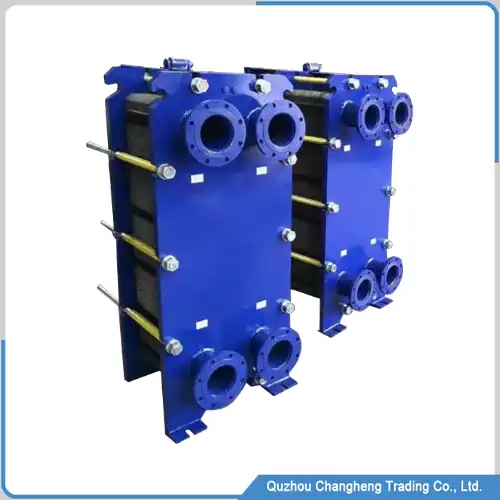

Shell and tube heat exchanger is a commonly used heat exchange equipment, consisting of components such as shell and tube, tube bundle, and tube plate.

Its main working principle is to utilize the temperature difference inside and between pipes, transfer heat through the pipe wall, and achieve heat exchange between two or more fluids.

There are also various types of shell heat exchangers, such as spiral tube shell heat exchangers, air-cooled tube shell heat exchangers, air-insulated tube shell heat exchangers, etc,

Suitable types can be selected based on different process requirements and medium properties.

Advantages of shell and tube heat exchanger

1, Simple structure, convenient manufacturing, and low cost.

2, The tube bundle can freely stretch and has good thermal compensation ability.

3, Baffles and channels can be added as needed to change the fluid flow state and improve heat transfer efficiency.

4, Easy to clean and maintain, for fluids containing solid particles, shell and tube heat exchangers have better erosion resistance performance.

5, Strong pressure resistance, the inner part of the shell and tube heat exchanger is welded by argon arc welding,

and the pipeline is expanded, making its pressure resistance far superior to other types of heat exchangers

Shell and tube heat exchanger data

| No. | ITEM | DATA |

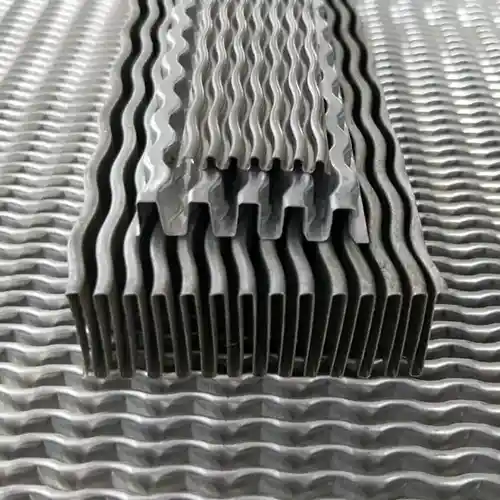

| 1 | Outer pipe material | iron stainless steel |

| 2 | Inner tube material | copper stainless steel iron |

| 3 | Pipe layout | staggered |

| 4 | Heat exchange medium | water, oil, other |

| 5 | Heat exchange type | cross flow |

| 6 | Maximum pressure | 16mpa |

| 7 | Heat exchange efficiency | customized |

| 8 | Inner tube structure | straight, rotating |

Shell and tube heat exchanger application

1, Chemical Industry

Chemical production requires a large amount of heat and cooling, and shell and tube heat exchangers play an important role in this.

It can be used for heat transfer in processes such as heating, cooling, evaporation, and condensation.

2, Food and Beverage Industry

In food and beverage production, shell and tube heat exchangers are used for heat transfer during heating, cooling, mixing, and disinfection processes.

3, Energy industry

In the fields of solar energy, geothermal energy, and industrial waste heat recovery, shell and tube heat exchangers are used for heat transfer and conversion.

4, Power industry

In the process of power production and transmission, shell and tube heat exchangers are used for heating and cooling steam, as well as heating cooling water.

5, Ship and Aerospace

In the field of ship and aerospace, shell and tube heat exchangers are used for fuel cooling, lubricating oil heating and cooling, etc.

Overall, shell and tube heat exchangers have a wide range of applications in various fields,

including chemical, food, energy, aerospace, and more.

In different application fields,

shell and tube heat exchangers need to be designed and manufactured according to specific usage environments and requirements to meet different application requirements.

Overall, shell and tube heat exchangers have their advantages in certain specific application scenarios,

but there may be some limitations under certain specific usage conditions.

When choosing to use shell and tube heat exchangers,

it is necessary to consider the specific usage environment and requirements comprehensively.

wechat

wechat